The global Wheel Flange Lubrication System Market study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments including By Type (Solid Stick System, Spray System), By Application (High-Speed Trains, Freight Trains, Passenger Trains).

The Wheel Flange Lubrication System Market in 2024 is witnessing significant growth, driven by the increasing demand for railway infrastructure maintenance solutions, rising concerns regarding rail safety and operational efficiency, and advancements in lubrication technologies. Wheel flange lubrication systems play a critical role in reducing friction, wear, and noise at the wheel-rail interface, thereby improving wheel and rail longevity, energy efficiency, and operational reliability. The market is experiencing a surge in demand for automated, intelligent lubrication systems equipped with advanced features such as predictive maintenance algorithms, remote monitoring, and data analytics to optimize lubricant usage, reduce maintenance costs, and enhance railway performance. Moreover, the integration of wheel flange lubrication systems with railway signaling and control systems is enabling proactive lubrication strategies based on real-time operational conditions and traffic dynamics, driving market growth and innovation.

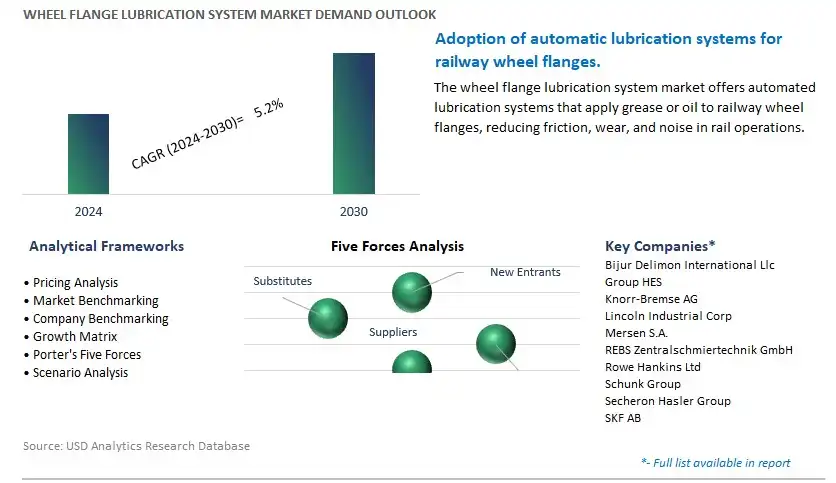

The global Wheel Flange Lubrication System market is highly competitive with a large number of companies focusing on niche market segments. Amidst intense competitive conditions, Wheel Flange Lubrication System Companies are investing in new product launches and strengthening distribution channels. Key companies operating in the Wheel Flange Lubrication System Market Industry include- Bijur Delimon International Llc, Group HES, Knorr-Bremse AG, Lincoln Industrial Corp, Mersen S.A., REBS Zentralschmiertechnik GmbH, Rowe Hankins Ltd, Schunk Group, Secheron Hasler Group, SKF AB.

The Wheel Flange Lubrication System Market is experiencing a prominent trend driven by the increasing adoption of automated lubrication systems for railway wheel flanges. Rail operators and maintenance providers are transitioning towards automated wheel flange lubrication systems to improve operational efficiency, reduce maintenance costs, and enhance safety. These automated systems utilize sensors and controllers to precisely apply lubricants to the wheel flanges of rolling stock as they pass through lubrication stations or trackside equipment. By automating the lubrication process, rail operators can ensure consistent and optimal lubrication levels, prolonging wheel and rail life while minimizing wear, noise, and friction. As railway networks strive for smoother, quieter, and more reliable operations, the demand for automated wheel flange lubrication systems continues to grow, driving market expansion towards advanced lubrication solutions.

A significant driver propelling the Wheel Flange Lubrication System Market is the increasing focus on rail safety and infrastructure maintenance by railway authorities and operators. Rail transport plays a vital role in global transportation networks, carrying passengers and freight over long distances. However, the heavy loads, high speeds, and harsh operating conditions experienced by railway rolling stock can lead to accelerated wear and tear on wheels and tracks, increasing the risk of derailments and costly downtime. Wheel flange lubrication systems help mitigate these risks by reducing friction and wear at the wheel-rail interface, improving wheel and track longevity while enhancing operational safety and reliability. As rail operators prioritize safety, reliability, and cost-effectiveness in their maintenance strategies, the demand for wheel flange lubrication systems as a preventive maintenance solution continues to rise, driving market growth.

An emerging opportunity in the Wheel Flange Lubrication System Market lies in the expansion into emerging rail markets and high-speed rail networks. As urbanization, population growth, and economic development drive the expansion of rail infrastructure worldwide, there is a growing demand for advanced maintenance solutions to support new rail projects and existing networks. Emerging rail markets in regions such as Asia-Pacific, Latin America, and Africa present untapped opportunities for wheel flange lubrication system providers to establish a presence and cater to the evolving needs of rail operators. Moreover, the proliferation of high-speed rail networks in both developed and emerging economies creates demand for specialized lubrication solutions capable of meeting the unique requirements of high-speed operations. By leveraging their expertise and technology offerings, wheel flange lubrication system manufacturers can capitalize on these opportunities to expand their market reach and drive business growth in emerging rail markets and high-speed rail segments.

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger TrainsGeographical Analysis

North America (United States, Canada, Mexico)

Europe (Germany, France, United Kingdom, Spain, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Rest of Asia Pacific)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa

Bijur Delimon International Llc

Group HES

Knorr-Bremse AG

Lincoln Industrial Corp

Mersen S.A.

REBS Zentralschmiertechnik GmbH

Rowe Hankins Ltd

Schunk Group

Secheron Hasler Group

SKF AB

*- List not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Wheel Flange Lubrication System Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Analyzed

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Wheel Flange Lubrication System Market Size Outlook, $ Million, 2021 to 2030

3.2 Wheel Flange Lubrication System Market Outlook by Type, $ Million, 2021 to 2030

3.3 Wheel Flange Lubrication System Market Outlook by Product, $ Million, 2021 to 2030

3.4 Wheel Flange Lubrication System Market Outlook by Application, $ Million, 2021 to 2030

3.5 Wheel Flange Lubrication System Market Outlook by Key Countries, $ Million, 2021 to 2030

4 Market Dynamics

4.1 Key Driving Forces of Wheel Flange Lubrication System Industry

4.2 Key Market Trends in Wheel Flange Lubrication System Industry

4.3 Potential Opportunities in Wheel Flange Lubrication System Industry

4.4 Key Challenges in Wheel Flange Lubrication System Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Wheel Flange Lubrication System Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Wheel Flange Lubrication System Market Outlook by Segments

7.1 Wheel Flange Lubrication System Market Outlook by Segments, $ Million, 2021- 2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

8 North America Wheel Flange Lubrication System Market Analysis and Outlook To 2030

8.1 Introduction to North America Wheel Flange Lubrication System Markets in 2024

8.2 North America Wheel Flange Lubrication System Market Size Outlook by Country, 2021-2030

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Wheel Flange Lubrication System Market size Outlook by Segments, 2021-2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

9 Europe Wheel Flange Lubrication System Market Analysis and Outlook To 2030

9.1 Introduction to Europe Wheel Flange Lubrication System Markets in 2024

9.2 Europe Wheel Flange Lubrication System Market Size Outlook by Country, 2021-2030

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Wheel Flange Lubrication System Market Size Outlook by Segments, 2021-2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

10 Asia Pacific Wheel Flange Lubrication System Market Analysis and Outlook To 2030

10.1 Introduction to Asia Pacific Wheel Flange Lubrication System Markets in 2024

10.2 Asia Pacific Wheel Flange Lubrication System Market Size Outlook by Country, 2021-2030

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Wheel Flange Lubrication System Market size Outlook by Segments, 2021-2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

11 South America Wheel Flange Lubrication System Market Analysis and Outlook To 2030

11.1 Introduction to South America Wheel Flange Lubrication System Markets in 2024

11.2 South America Wheel Flange Lubrication System Market Size Outlook by Country, 2021-2030

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Wheel Flange Lubrication System Market size Outlook by Segments, 2021-2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

12 Middle East and Africa Wheel Flange Lubrication System Market Analysis and Outlook To 2030

12.1 Introduction to Middle East and Africa Wheel Flange Lubrication System Markets in 2024

12.2 Middle East and Africa Wheel Flange Lubrication System Market Size Outlook by Country, 2021-2030

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Wheel Flange Lubrication System Market size Outlook by Segments, 2021-2030

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

List of Companies

Bijur Delimon International Llc

Group HES

Knorr-Bremse AG

Lincoln Industrial Corp

Mersen S.A.

REBS Zentralschmiertechnik GmbH

Rowe Hankins Ltd

Schunk Group

Secheron Hasler Group

SKF AB

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Type

Solid Stick System

Spray System

By Application

High Speed Trains

Freight Trains

Passenger Trains

The global Wheel Flange Lubrication System Market is one of the lucrative growth markets, poised to register a 5.2% growth (CAGR) between 2024 and 2030.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Bijur Delimon International Llc, Group HES, Knorr-Bremse AG, Lincoln Industrial Corp, Mersen S.A., REBS Zentralschmiertechnik GmbH, Rowe Hankins Ltd, Schunk Group, Secheron Hasler Group, SKF AB

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2030; Currency: USD; Volume