The global UV Adhesives Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Resin (Acrylic, Cyanoacrylate, Epoxy, Silicone, Polyurethane, Others), By Application (Medical, Electronics, Glass Bonding, Packaging, Transportation, Industrial Assembly, Others).

UV adhesives to be versatile and efficient bonding solutions in various industries in 2024, offering rapid curing, strong adhesion, and excellent optical clarity. These adhesives are formulated with photoinitiators that undergo polymerization when exposed to ultraviolet (UV) light, resulting in fast and reliable bonding of substrates such as glass, plastics, metals, and ceramics. UV adhesives find applications in electronics assembly, medical device manufacturing, optical fabrication, and automotive assembly, where rapid processing times and high bond strength are critical. In electronics, UV adhesives are used for bonding components, sealing housings, and encapsulating delicate electronic circuits, providing protection against moisture, dust, and vibration. Similarly, in medical devices, UV adhesives are employed for bonding surgical instruments, catheters, and diagnostic devices, ensuring biocompatibility and sterilization compatibility. With advancements in UV curing technology, formulation chemistry, and application methods, UV adhesives to offer innovative solutions for bonding challenges in modern manufacturing processes, driving efficiency, reliability, and performance across diverse industries.

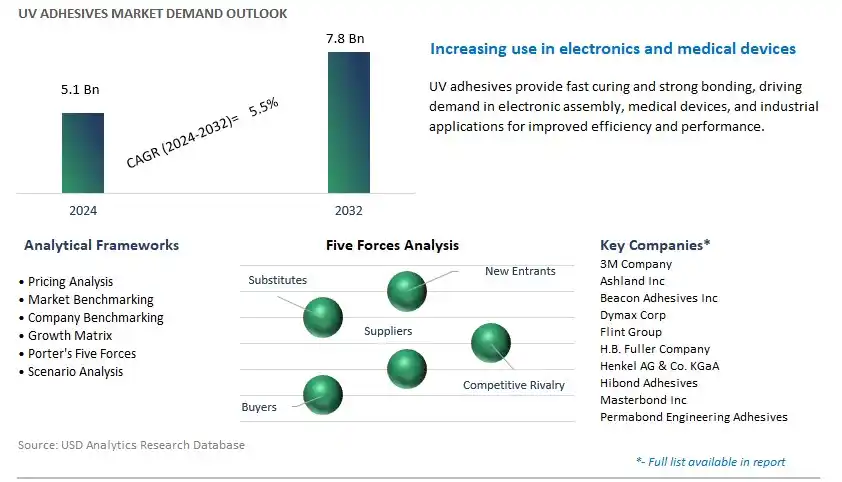

The market report analyses the leading companies in the industry including 3M Company, Ashland Inc, Beacon Adhesives Inc, Dymax Corp, Flint Group, H.B. Fuller Company, Henkel AG & Co. KGaA, Hibond Adhesives, Masterbond Inc, Permabond Engineering Adhesives, and others.

A significant market trend in the UV adhesives industry is the growing demand for high-performance bonding solutions in electronics and medical devices. UV adhesives, also known as ultraviolet-curable adhesives, offer fast curing times, high bond strength, and excellent optical clarity, making them ideal for applications requiring precise assembly, miniaturization, and reliability. This trend is driven by the increasing complexity and miniaturization of electronic devices, where UV adhesives are used for bonding components such as displays, touchscreens, sensors, and microelectronics. Additionally, in the medical device industry, UV adhesives play a critical role in bonding medical implants, disposable devices, and diagnostic equipment, where biocompatibility, sterilizability, and precision bonding are essential. As industries continue to innovate and demand higher performance from adhesive technologies, the market for UV adhesives is experiencing growth and expanding applications in electronics and medical device manufacturing.

The driver behind the growth of the UV adhesives market is advancements in UV curing technology and materials. Innovations in UV light sources, photoinitiators, and resin formulations have led to improvements in curing speed, depth of cure, and bond strength of UV adhesives. UV LED technology, in particular, offers advantages such as energy efficiency, longer service life, and precise control over curing parameters, enabling manufacturers to achieve faster production cycles and higher productivity. Additionally, developments in UV adhesives with tailored properties such as thermal conductivity, flexibility, and chemical resistance expand their applicability in demanding environments such as automotive, aerospace, and consumer electronics. As manufacturers seek to optimize assembly processes, reduce costs, and improve product performance, the demand for UV adhesives as a versatile bonding solution driven by technological advancements continues to rise, shaping the market towards greater adoption in various industries.

An opportunity for growth and diversification in the UV adhesives market lies in expansion into automotive interior assembly and composite bonding applications. While UV adhesives are commonly used in electronics and medical devices, there is potential for penetration into new sectors such as automotive manufacturing. In automotive interior assembly, UV adhesives can be utilized for bonding trim components, dashboard assemblies, and interior panels, offering advantages such as rapid curing, high bond strength, and aesthetic appeal. Similarly, in composite bonding applications, UV adhesives provide a lightweight, cost-effective alternative to mechanical fastening methods for joining composite materials in automotive body panels, aircraft interiors, and sporting goods. By exploring new applications and market segments in automotive manufacturing, UV adhesive manufacturers can diversify their product offerings, expand their customer base, and capitalize on opportunities for growth and market expansion beyond traditional electronics and medical device markets.

Within the UV Adhesives market, the Acrylic Resin segment is the largest and most significant. In particular, acrylic UV adhesives offer a wide range of advantages, including excellent adhesion to various substrates, fast curing times, high transparency, and resistance to yellowing and weathering. These properties make acrylic UV adhesives suitable for diverse applications across industries such as automotive, electronics, construction, and medical devices. Additionally, acrylic UV adhesives are solvent-free and exhibit low volatility during curing, making them environmentally friendly and safe for use in enclosed environments. Moreover, the versatility of acrylic resins allows for the formulation of UV adhesives with tailored properties to meet specific application requirements, further enhancing their utility and widespread adoption. Furthermore, advancements in acrylic resin chemistry and UV curing technology continue to drive innovation and expand the application scope of acrylic-based UV adhesives, solidifying their position as the largest segment within the UV Adhesives market.

Among the various applications in the UV Adhesives market, the Electronics sector stands out as the fastest-growing segment. In particular, the electronics industry relies heavily on UV adhesives for the assembly and bonding of electronic components such as semiconductors, circuit boards, displays, and sensors. UV adhesives offer numerous advantages for electronics manufacturing, including fast curing times, high bond strength, excellent thermal and chemical resistance, and compatibility with delicate electronic materials. Moreover, the trend towards miniaturization and increased functionality of electronic devices drives the demand for UV adhesives with precise application control and low outgassing properties to ensure reliable performance in compact and high-performance electronic assemblies. Additionally, the expanding applications of UV adhesives in emerging technologies such as wearable devices, flexible electronics, and 5G infrastructure further contribute to the sector's rapid growth. Furthermore, ongoing advancements in UV adhesive formulations, including the development of low-temperature curing adhesives and conductive UV adhesives for advanced electronic applications, continue to fuel innovation and drive the adoption of UV adhesives in the electronics industry. As a result, the Electronics Application segment is experiencing significant expansion within the UV Adhesives market, with sustained growth anticipated as electronic device manufacturers continue to innovate and demand high-performance bonding solutions.

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

3M Company

Ashland Inc

Beacon Adhesives Inc

Dymax Corp

Flint Group

H.B. Fuller Company

Henkel AG & Co. KGaA

Hibond Adhesives

Masterbond Inc

Permabond Engineering Adhesives

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 UV Adhesives Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global UV Adhesives Market Size Outlook, $ Million, 2021 to 2032

3.2 UV Adhesives Market Outlook by Type, $ Million, 2021 to 2032

3.3 UV Adhesives Market Outlook by Product, $ Million, 2021 to 2032

3.4 UV Adhesives Market Outlook by Application, $ Million, 2021 to 2032

3.5 UV Adhesives Market Outlook by Key Countries, $ Million, 2021 to 2032

4 Market Dynamics

4.1 Key Driving Forces of UV Adhesives Industry

4.2 Key Market Trends in UV Adhesives Industry

4.3 Potential Opportunities in UV Adhesives Industry

4.4 Key Challenges in UV Adhesives Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global UV Adhesives Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global UV Adhesives Market Outlook by Segments

7.1 UV Adhesives Market Outlook by Segments, $ Million, 2021- 2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

8 North America UV Adhesives Market Analysis and Outlook To 2032

8.1 Introduction to North America UV Adhesives Markets in 2024

8.2 North America UV Adhesives Market Size Outlook by Country, 2021-2032

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America UV Adhesives Market size Outlook by Segments, 2021-2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

9 Europe UV Adhesives Market Analysis and Outlook To 2032

9.1 Introduction to Europe UV Adhesives Markets in 2024

9.2 Europe UV Adhesives Market Size Outlook by Country, 2021-2032

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe UV Adhesives Market Size Outlook by Segments, 2021-2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

10 Asia Pacific UV Adhesives Market Analysis and Outlook To 2032

10.1 Introduction to Asia Pacific UV Adhesives Markets in 2024

10.2 Asia Pacific UV Adhesives Market Size Outlook by Country, 2021-2032

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific UV Adhesives Market size Outlook by Segments, 2021-2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

11 South America UV Adhesives Market Analysis and Outlook To 2032

11.1 Introduction to South America UV Adhesives Markets in 2024

11.2 South America UV Adhesives Market Size Outlook by Country, 2021-2032

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America UV Adhesives Market size Outlook by Segments, 2021-2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

12 Middle East and Africa UV Adhesives Market Analysis and Outlook To 2032

12.1 Introduction to Middle East and Africa UV Adhesives Markets in 2024

12.2 Middle East and Africa UV Adhesives Market Size Outlook by Country, 2021-2032

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa UV Adhesives Market size Outlook by Segments, 2021-2032

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

3M Company

Ashland Inc

Beacon Adhesives Inc

Dymax Corp

Flint Group

H.B. Fuller Company

Henkel AG & Co. KGaA

Hibond Adhesives

Masterbond Inc

Permabond Engineering Adhesives

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Resin

Acrylic

Cyanoacrylate

Epoxy

Silicone

Polyurethane

Others

By Application

Medical

Electronics

Glass Bonding

Packaging

Transportation

Industrial Assembly

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global UV Adhesives Market Size is valued at $5.1 Billion in 2024 and is forecast to register a growth rate (CAGR) of 5.5% to reach $7.8 Billion by 2032.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

3M Company, Ashland Inc, Beacon Adhesives Inc, Dymax Corp, Flint Group, H.B. Fuller Company, Henkel AG & Co. KGaA, Hibond Adhesives, Masterbond Inc, Permabond Engineering Adhesives

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2032; Currency: Revenue (USD); Volume