The global Titanium Mill Products Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Product (Sheets & Plates, Billets & Bars, Others), By Application (Aviation Industry, Chemical Industry, Ocean Engineering, Ship, Others).

The titanium mill products market is experiencing robust growth driven by increasing demand in aerospace, medical, chemical processing, and automotive industries for lightweight, corrosion-resistant, and high-strength materials. Key trends shaping the future of the industry include the rising adoption of titanium alloys such as Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, and Ti-6Al-2Nb-1Ta for critical components and structures in aircraft engines, orthopedic implants, chemical reactors, and automotive parts, driven by their excellent mechanical properties and biocompatibility. Moreover, there's a growing emphasis on material innovation and additive manufacturing technologies to expand the application range, reduce production costs, and enable complex geometries and lattice structures in titanium products. Additionally, advancements in titanium extraction, alloy development, and processing techniques are driving innovation and market expansion, enabling manufacturers to offer high-performance solutions for demanding applications and emerging market needs, thereby fueling market growth and competitiveness in the global titanium mill products market.

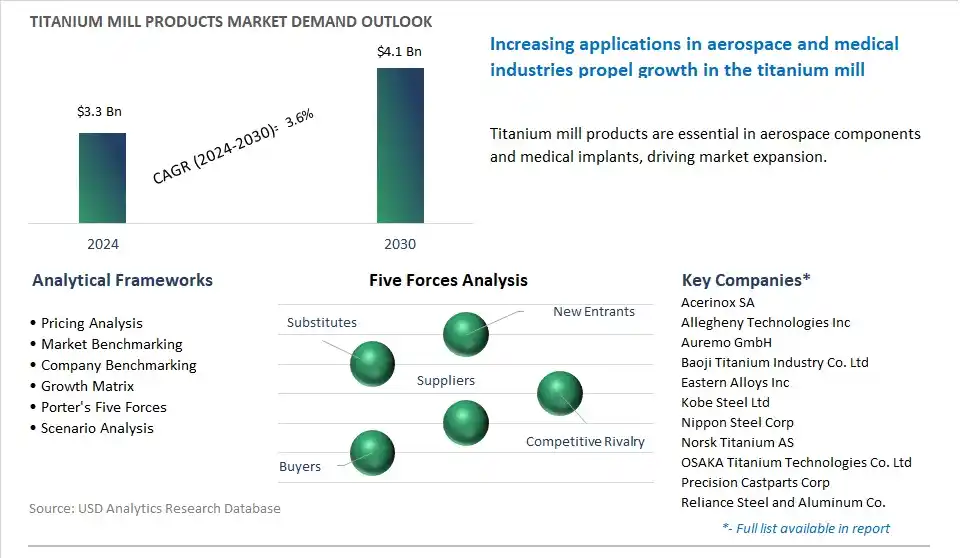

The market report analyses the leading companies in the industry including Acerinox SA, Allegheny Technologies Inc, Auremo GmbH, Baoji Titanium Industry Co. Ltd, Eastern Alloys Inc, Kobe Steel Ltd, Nippon Steel Corp, Norsk Titanium AS, OSAKA Titanium Technologies Co. Ltd, Precision Castparts Corp, Reliance Steel and Aluminum Co., Rostec, Smiths Metal Centres Ltd, Supra Alloys, Titan Engineering Pte Ltd, Titanium Industries Inc, Toho Titanium Co. Ltd, Tricor Metals Inc, United Titanium Inc, Western Superconducting Technologies Co Ltd.

The most prominent market trend for titanium mill products is the increasing adoption of titanium in aerospace and defense industries. Titanium's unique combination of high strength-to-weight ratio, corrosion resistance, and heat tolerance makes it highly desirable for manufacturing critical components in aircraft, spacecraft, missiles, and military vehicles. With advancements in aerospace technology, the demand for titanium mill products such as titanium sheets, plates, bars, and tubes continues to grow, driven by the need for lightweight, durable, and high-performance materials to enhance aircraft efficiency, fuel economy, and mission capabilities. This trend is fueled by ongoing aerospace development programs, defense modernization initiatives, and the expansion of commercial aviation, stimulating growth and innovation in the titanium mill products market.

A key market driver for titanium mill products is the expansion of industrial applications and manufacturing technologies. Titanium's exceptional properties make it an attractive material for various industrial sectors such as automotive, medical, energy, and consumer electronics. With advancements in titanium processing techniques, including powder metallurgy, additive manufacturing, and advanced machining methods, manufacturers can produce complex titanium components with improved efficiency, accuracy, and cost-effectiveness. The expansion of industrial applications, coupled with ongoing research and development efforts to optimize titanium alloys and production processes, drives the demand for titanium mill products, creating opportunities for manufacturers to innovate and diversify their product offerings to meet diverse market needs.

An exciting opportunity in the titanium mill products market lies in penetration into emerging markets such as renewable energy and biomedical devices. While titanium has traditionally been used in aerospace and defense, there's potential for growth in sectors that demand high-performance materials for sustainable energy generation and medical advancements. In the renewable energy sector, titanium mill products can be utilized in the manufacturing of components for wind turbines, solar panels, and hydrogen fuel cells, where corrosion resistance, durability, and lightweight properties are essential for long-term performance. Similarly, in the biomedical field, titanium offers biocompatibility, corrosion resistance, and mechanical strength, making it suitable for implants, prosthetics, and surgical instruments. By targeting emerging applications and markets, titanium mill product manufacturers can diversify their customer base, explore new revenue streams, and capitalize on the growing demand for titanium in specialized sectors. Additionally, the development of innovative titanium alloys, surface treatments, and fabrication techniques tailored to specific application requirements presents opportunities for differentiation and value creation in the market. This opportunity allows titanium mill product manufacturers to expand their market reach, strengthen their competitive position, and drive growth through strategic partnerships and initiatives focused on technological innovation and market expansion.

The largest segment in the Titanium Mill Products Market is Sheets & Plates. This dominance is driven by that make sheets and plates the preferred choice in various industries and applications. Sheets and plates made from titanium offer Diverse key advantages that make them highly desirable for use in aerospace, automotive, medical, chemical processing, and other industries. titanium sheets and plates exhibit exceptional strength-to-weight ratios, making them ideal for applications where high strength and low weight are critical, such as aerospace components, structural assemblies, and automotive parts. Further, titanium sheets and plates offer excellent corrosion resistance, thermal stability, and biocompatibility, making them suitable for demanding environments and applications, including chemical processing equipment, medical implants, and marine structures. In addition, titanium sheets and plates can be easily fabricated, machined, and welded to meet specific design requirements and performance criteria, offering versatility and flexibility in manufacturing processes. Additionally, advancements in titanium processing technologies have improved the quality, consistency, and cost-effectiveness of titanium sheets and plates, further driving their adoption across industries. With the growing demand for lightweight, durable, and corrosion-resistant materials in various industrial sectors, the demand for titanium sheets and plates is expected to remain strong, maintaining their position as the largest segment in the Titanium Mill Products Market.

The fastest-growing segment in the Titanium Mill Products Market is the Aviation Industry. This rapid growth is driven by the increasing demand for titanium mill products in the aviation sector. Titanium offers Diverse unique properties that make it highly desirable for aerospace applications. titanium is exceptionally lightweight yet strong, making it ideal for aircraft components where high strength-to-weight ratios are critical for fuel efficiency and performance. Further, titanium exhibits excellent corrosion resistance, allowing for extended service life and reduced maintenance costs, which are essential considerations for aircraft operating in harsh environments and extreme conditions. In addition, titanium has excellent fatigue resistance and thermal stability, making it suitable for use in high-temperature environments, such as jet engines and airframes, where other materials degrade or fail under stress. Additionally, advancements in titanium processing technologies have improved manufacturing efficiencies, reduced production costs, and expanded the range of aerospace components that can be made from titanium. Furthermore, as the aerospace industry continues to innovate and develop next-generation aircraft designs, there is a growing demand for advanced materials like titanium to meet the performance, efficiency, and sustainability goals of modern aviation. With the increasing adoption of titanium mill products in aircraft structures, engines, landing gear, and other critical components, the demand for titanium in the aviation industry is expected to continue growing rapidly, making it the fastest-growing segment in the Titanium Mill Products Market.

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

Regions Included

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Acerinox SA

Allegheny Technologies Inc

Auremo GmbH

Baoji Titanium Industry Co. Ltd

Eastern Alloys Inc

Kobe Steel Ltd

Nippon Steel Corp

Norsk Titanium AS

OSAKA Titanium Technologies Co. Ltd

Precision Castparts Corp

Reliance Steel and Aluminum Co.

Rostec

Smiths Metal Centres Ltd

Supra Alloys

Titan Engineering Pte Ltd

Titanium Industries Inc

Toho Titanium Co. Ltd

Tricor Metals Inc

United Titanium Inc

Western Superconducting Technologies Co Ltd

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Titanium Mill Products Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Titanium Mill Products Market Size Outlook, $ Million, 2021 to 2030

3.2 Titanium Mill Products Market Outlook by Type, $ Million, 2021 to 2030

3.3 Titanium Mill Products Market Outlook by Product, $ Million, 2021 to 2030

3.4 Titanium Mill Products Market Outlook by Application, $ Million, 2021 to 2030

3.5 Titanium Mill Products Market Outlook by Key Countries, $ Million, 2021 to 2030

4 Market Dynamics

4.1 Key Driving Forces of Titanium Mill Products Industry

4.2 Key Market Trends in Titanium Mill Products Industry

4.3 Potential Opportunities in Titanium Mill Products Industry

4.4 Key Challenges in Titanium Mill Products Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Titanium Mill Products Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Titanium Mill Products Market Outlook by Segments

7.1 Titanium Mill Products Market Outlook by Segments, $ Million, 2021- 2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

8 North America Titanium Mill Products Market Analysis and Outlook To 2030

8.1 Introduction to North America Titanium Mill Products Markets in 2024

8.2 North America Titanium Mill Products Market Size Outlook by Country, 2021-2030

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Titanium Mill Products Market size Outlook by Segments, 2021-2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

9 Europe Titanium Mill Products Market Analysis and Outlook To 2030

9.1 Introduction to Europe Titanium Mill Products Markets in 2024

9.2 Europe Titanium Mill Products Market Size Outlook by Country, 2021-2030

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Titanium Mill Products Market Size Outlook by Segments, 2021-2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

10 Asia Pacific Titanium Mill Products Market Analysis and Outlook To 2030

10.1 Introduction to Asia Pacific Titanium Mill Products Markets in 2024

10.2 Asia Pacific Titanium Mill Products Market Size Outlook by Country, 2021-2030

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Titanium Mill Products Market size Outlook by Segments, 2021-2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

11 South America Titanium Mill Products Market Analysis and Outlook To 2030

11.1 Introduction to South America Titanium Mill Products Markets in 2024

11.2 South America Titanium Mill Products Market Size Outlook by Country, 2021-2030

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Titanium Mill Products Market size Outlook by Segments, 2021-2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

12 Middle East and Africa Titanium Mill Products Market Analysis and Outlook To 2030

12.1 Introduction to Middle East and Africa Titanium Mill Products Markets in 2024

12.2 Middle East and Africa Titanium Mill Products Market Size Outlook by Country, 2021-2030

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Titanium Mill Products Market size Outlook by Segments, 2021-2030

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

Acerinox SA

Allegheny Technologies Inc

Auremo GmbH

Baoji Titanium Industry Co. Ltd

Eastern Alloys Inc

Kobe Steel Ltd

Nippon Steel Corp

Norsk Titanium AS

OSAKA Titanium Technologies Co. Ltd

Precision Castparts Corp

Reliance Steel and Aluminum Co.

Rostec

Smiths Metal Centres Ltd

Supra Alloys

Titan Engineering Pte Ltd

Titanium Industries Inc

Toho Titanium Co. Ltd

Tricor Metals Inc

United Titanium Inc

Western Superconducting Technologies Co Ltd

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Product

Sheets & Plates

Billets & Bars

Others

By Application

Aviation Industry

Chemical Industry

Ocean Engineering

Ship

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Titanium Mill Products is forecast to reach $4.1 Billion in 2030 from $3.3 Billion in 2024, registering a CAGR of 3.6%

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Acerinox SA, Allegheny Technologies Inc, Auremo GmbH, Baoji Titanium Industry Co. Ltd, Eastern Alloys Inc, Kobe Steel Ltd, Nippon Steel Corp, Norsk Titanium AS, OSAKA Titanium Technologies Co. Ltd, Precision Castparts Corp, Reliance Steel and Aluminum Co., Rostec, Smiths Metal Centres Ltd, Supra Alloys, Titan Engineering Pte Ltd, Titanium Industries Inc, Toho Titanium Co. Ltd, Tricor Metals Inc, United Titanium Inc, Western Superconducting Technologies Co Ltd

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2030; Currency: Revenue (USD); Volume