The global Subsea Thermal Insulation Materials Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Type (Polyurethane, Polypropylene, Silicone Rubber, Epoxy, Aerogel, Others), By Application (Pipe-in-Pipe, Pipe Cover, Equipment, Field Joints, Others).

Subsea thermal insulation materials play a crucial role in offshore oil and gas production facilities, ensuring the integrity and efficiency of subsea pipelines and equipment in 2024. These materials are designed to provide thermal insulation and corrosion protection for pipelines, flowlines, risers, and subsea equipment operating in harsh environments at extreme depths. In deepwater drilling operations, subsea thermal insulation materials help maintain the temperature of transported fluids, preventing hydrate formation and ensuring the flow of hydrocarbons. With advancements in material science and engineering, subsea thermal insulation materials offer enhanced performance, reliability, and durability, contributing to the safe and efficient operation of offshore oil and gas projects in challenging subsea conditions.

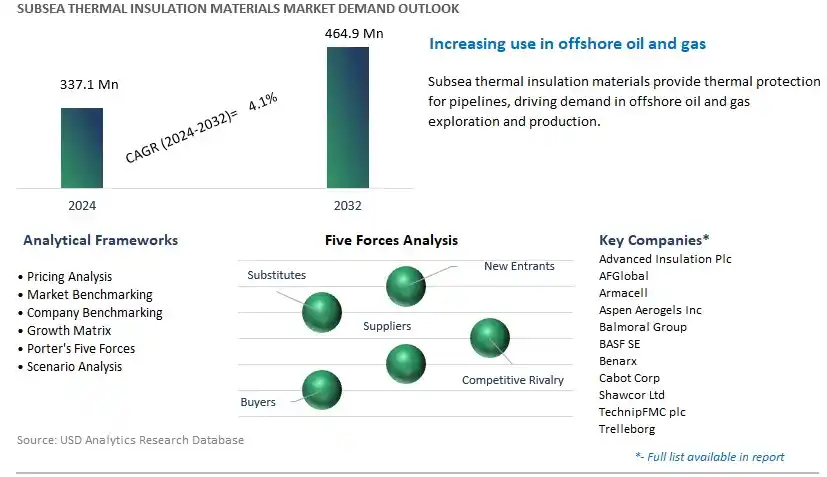

The market report analyses the leading companies in the industry including Advanced Insulation Plc, AFGlobal, Armacell, Aspen Aerogels Inc, Balmoral Group, BASF SE, Benarx, Cabot Corp, Shawcor Ltd, TechnipFMC plc, Trelleborg, and others.

A prominent trend in the subsea thermal insulation materials market is the increasing demand for materials that can withstand harsh subsea environments in oil and gas exploration and production activities. This trend is driven by the growing need to extract hydrocarbons from deepwater and ultra-deepwater reserves, where temperatures and pressures are extreme. Subsea thermal insulation materials are essential for maintaining the integrity and performance of subsea infrastructure such as pipelines, risers, and equipment by providing thermal insulation, corrosion protection, and mechanical strength. As offshore oil and gas projects move into deeper waters and more challenging environments, the demand for advanced thermal insulation materials capable of withstanding high temperatures, pressure differentials, and corrosive conditions is expected to rise.

The primary driver for the subsea thermal insulation materials market is technological advancements in offshore energy extraction techniques, which require materials that can withstand increasingly challenging operating conditions. As oil and gas companies explore deeper offshore reserves and develop complex subsea infrastructure, there is a growing need for thermal insulation materials that can ensure the safety, reliability, and longevity of equipment and pipelines. Advances in material science, polymer chemistry, and composite manufacturing enable the development of insulation materials with superior thermal conductivity, mechanical properties, and resistance to hydrostatic pressure and corrosive fluids. Additionally, innovations in subsea insulation systems, such as pre-fabricated jacketing, vacuum insulation panels, and syntactic foam coatings, improve installation efficiency and reduce lifecycle costs, driving adoption in offshore energy projects.

A significant opportunity for the subsea thermal insulation materials market lies in expanding into renewable energy and offshore wind farm applications, where thermal insulation is essential for maintaining operational efficiency and reliability in harsh marine environments. As the global focus shifts towards reducing carbon emissions and transitioning towards renewable energy sources, there is a growing investment in offshore wind farms located in deepwater and offshore locations. Subsea thermal insulation materials play a critical role in protecting underwater cables, subsea foundations, and electrical components from temperature fluctuations, seawater ingress, and mechanical damage, ensuring the long-term performance and reliability of offshore wind installations. By offering insulation materials tailored to the unique requirements of offshore wind farms, such as durability, buoyancy, and resistance to marine growth, manufacturers can capitalize on the growing demand for renewable energy infrastructure and establish themselves as key suppliers in the offshore wind market. Additionally, partnerships with wind farm developers, research collaborations with renewable energy institutes, and participation in government-funded initiatives present opportunities for innovation and market expansion in the burgeoning offshore renewable energy sector.

Within the Subsea Thermal Insulation Materials Market segmented by type, Polyurethane is the largest segment, driven by its exceptional thermal insulation properties, durability, and versatility in subsea applications. Polyurethane insulation materials are widely utilized in subsea pipelines, risers, and equipment to mitigate heat loss and maintain optimal operating temperatures in challenging offshore environments. The excellent thermal conductivity of polyurethane helps minimize energy loss and ensures the efficient performance of subsea infrastructure, particularly in deep-water oil and gas production. Moreover, polyurethane materials offer resistance to corrosion, water ingress, and mechanical stress, making them suitable for long-term subsea installations. Additionally, advancements in polyurethane technology have led to the development of lightweight and environmentally friendly formulations, further enhancing their appeal in the subsea industry. As offshore exploration and production activities continue to expand globally, driven by the demand for hydrocarbon resources, the Polyurethane segment maintains its dominance in the subsea thermal insulation materials market, offering reliable solutions for efficient and reliable subsea operations.

Within the Subsea Thermal Insulation Materials Market segmented by application, the Pipe Cover segment is the fastest-growing, driven by increasing demand for thermal insulation solutions in subsea pipelines. Pipe cover insulation plays a crucial role in maintaining the temperature of subsea pipelines, preventing heat loss, and ensuring the efficient transportation of fluids in harsh offshore environments. As offshore oil and gas exploration ventures into deeper and more challenging waters, the need for reliable thermal insulation materials to protect subsea pipelines from temperature fluctuations becomes increasingly critical. Additionally, the growing emphasis on energy efficiency and environmental sustainability in the oil and gas industry further fuels the demand for advanced thermal insulation solutions. The Pipe Cover segment is experiencing rapid growth as operators invest in subsea infrastructure upgrades and new projects to maximize production efficiency and minimize environmental impact. Moreover, advancements in insulation material technology, such as the development of high-performance polymers and aerogels, are driving innovation and adoption in the Pipe Cover segment, contributing to its accelerated growth in the subsea thermal insulation materials market.

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Advanced Insulation Plc

AFGlobal

Armacell

Aspen Aerogels Inc

Balmoral Group

BASF SE

Benarx

Cabot Corp

Shawcor Ltd

TechnipFMC plc

Trelleborg

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Subsea Thermal Insulation Materials Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Subsea Thermal Insulation Materials Market Size Outlook, $ Million, 2021 to 2032

3.2 Subsea Thermal Insulation Materials Market Outlook by Type, $ Million, 2021 to 2032

3.3 Subsea Thermal Insulation Materials Market Outlook by Product, $ Million, 2021 to 2032

3.4 Subsea Thermal Insulation Materials Market Outlook by Application, $ Million, 2021 to 2032

3.5 Subsea Thermal Insulation Materials Market Outlook by Key Countries, $ Million, 2021 to 2032

4 Market Dynamics

4.1 Key Driving Forces of Subsea Thermal Insulation Materials Industry

4.2 Key Market Trends in Subsea Thermal Insulation Materials Industry

4.3 Potential Opportunities in Subsea Thermal Insulation Materials Industry

4.4 Key Challenges in Subsea Thermal Insulation Materials Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Subsea Thermal Insulation Materials Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Subsea Thermal Insulation Materials Market Outlook by Segments

7.1 Subsea Thermal Insulation Materials Market Outlook by Segments, $ Million, 2021- 2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

8 North America Subsea Thermal Insulation Materials Market Analysis and Outlook To 2032

8.1 Introduction to North America Subsea Thermal Insulation Materials Markets in 2024

8.2 North America Subsea Thermal Insulation Materials Market Size Outlook by Country, 2021-2032

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Subsea Thermal Insulation Materials Market size Outlook by Segments, 2021-2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

9 Europe Subsea Thermal Insulation Materials Market Analysis and Outlook To 2032

9.1 Introduction to Europe Subsea Thermal Insulation Materials Markets in 2024

9.2 Europe Subsea Thermal Insulation Materials Market Size Outlook by Country, 2021-2032

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Subsea Thermal Insulation Materials Market Size Outlook by Segments, 2021-2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

10 Asia Pacific Subsea Thermal Insulation Materials Market Analysis and Outlook To 2032

10.1 Introduction to Asia Pacific Subsea Thermal Insulation Materials Markets in 2024

10.2 Asia Pacific Subsea Thermal Insulation Materials Market Size Outlook by Country, 2021-2032

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Subsea Thermal Insulation Materials Market size Outlook by Segments, 2021-2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

11 South America Subsea Thermal Insulation Materials Market Analysis and Outlook To 2032

11.1 Introduction to South America Subsea Thermal Insulation Materials Markets in 2024

11.2 South America Subsea Thermal Insulation Materials Market Size Outlook by Country, 2021-2032

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Subsea Thermal Insulation Materials Market size Outlook by Segments, 2021-2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

12 Middle East and Africa Subsea Thermal Insulation Materials Market Analysis and Outlook To 2032

12.1 Introduction to Middle East and Africa Subsea Thermal Insulation Materials Markets in 2024

12.2 Middle East and Africa Subsea Thermal Insulation Materials Market Size Outlook by Country, 2021-2032

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Subsea Thermal Insulation Materials Market size Outlook by Segments, 2021-2032

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

Advanced Insulation Plc

AFGlobal

Armacell

Aspen Aerogels Inc

Balmoral Group

BASF SE

Benarx

Cabot Corp

Shawcor Ltd

TechnipFMC plc

Trelleborg

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Type

Polyurethane

Polypropylene

Silicone Rubber

Epoxy

Aerogel

Others

By Application

Pipe-in-Pipe

Pipe Cover

Equipment

Field Joints

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Subsea Thermal Insulation Materials Market Size is valued at $337.1 Million in 2024 and is forecast to register a growth rate (CAGR) of 4.1% to reach $464.9 Million by 2032.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Advanced Insulation Plc, AFGlobal, Armacell, Aspen Aerogels Inc, Balmoral Group, BASF SE, Benarx, Cabot Corp, Shawcor Ltd, TechnipFMC plc, Trelleborg

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2032; Currency: Revenue (USD); Volume