Overhead Conveyor System Market study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments- By End-User (Automotive, Logistics and e-commerce, Food and beverage, Others), By Capacity (Up to 50 Kg, 50 to 500 Kg, Above 500 Kg).

The Overhead Conveyor System Market is driven by the need for automated material handling solutions to enhance efficiency, streamline production processes, and reduce operational costs. Overhead conveyor systems offer numerous advantages such as space optimization, flexibility, and high throughput, making them indispensable in a wide range of applications including manufacturing, warehousing, distribution, and logistics. The market is witnessing substantial growth driven by factors such as the expansion of e-commerce, the need for just-in-time manufacturing, and the growing emphasis on lean production principles. In addition, advancements in technology, such as the integration of sensors, robotics, and automation software, are further enhancing the capabilities and efficiency of overhead conveyor systems.

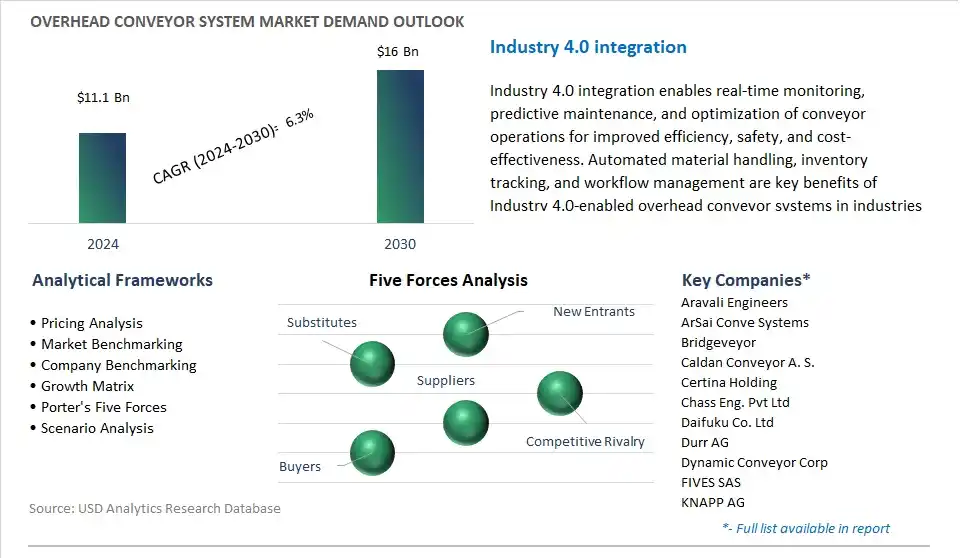

Aravali Engineers, ArSai Conve Systems, Bridgeveyor, Caldan Conveyor A. S., Certina Holding, Chass Eng. Pvt Ltd, Daifuku Co. Ltd, Durr AG, Dynamic Conveyor Corp, FIVES SAS, KNAPP AG, MIDEA Group Co. Ltd, Niko Helm Hellas SA, OCS Overhead Conveyor System Ltd, OMH Group, Pacline Conveyors Inc, psb intralogistics GmbH, Railtechniek B.V., Rapid Industries, Schonenberger Systeme GmbH, Siemens AG, SSI Schafer IT Solutions GmbH, United Engineering Industries

The Overhead Conveyor System market is witnessing the adoption of automation and Industry 4.0 technologies in manufacturing and logistics sectors. Companies are increasingly implementing overhead conveyor systems equipped with sensors, robotics, and digital connectivity to streamline material handling processes, improve production efficiency, and enhance supply chain agility. This trend reflects the industry's transition towards smart factories and automated warehouse solutions, leveraging advanced conveyor systems for seamless material flow and operations optimization.

Increasing demand for efficient material handling solutions across diverse industries, including automotive, food and beverage, e-commerce, and pharmaceuticals support the market. Overhead conveyor systems offer benefits such as space optimization, high throughput rates, reduced labor costs, and precise handling of goods, making them ideal for transporting products along assembly lines, distribution centers, and warehousing facilities. The emphasis on lean manufacturing, just-in-time production, and logistics efficiency drives the adoption of advanced conveyor technologies to meet operational demands and improve productivity.

The Overhead Conveyor System market presents significant opportunities driven by the expansion of e-commerce operations and warehouse automation initiatives. The rapid growth of online retail and fulfillment centers requires scalable and flexible conveyor solutions to handle diverse product types, order volumes, and delivery schedules. In addition, the trend towards omnichannel distribution, same-day delivery, and order customization drives the need for conveyor systems that support quick order processing, sorting, and fulfillment. Furthermore, the integration of robotics and AI-enabled technologies in overhead conveyor systems offers opportunities for advanced automation and intelligent material handling solutions, catering to the evolving needs of modern manufacturing and logistics environments.

The Logistics and e-commerce segment is the largest within the Overhead Conveyor System Market due to several key factors. In the logistics and e-commerce sectors, there is a high demand for efficient material handling solutions to streamline warehouse operations, order fulfillment, and distribution processes. Overhead conveyor systems offer advantages such as space optimization, automated material flow, scalability, and the ability to handle a wide range of products, making them essential for modern logistics and e-commerce facilities. In addition, with the growth of online retail, same-day delivery expectations, and the need for order accuracy, overhead conveyor systems play a crucial role in ensuring fast and reliable order processing while minimizing errors and labor costs. The strategic importance of overhead conveyor systems in optimizing supply chain logistics and meeting the demands of e-commerce drives their dominance as the largest segment within the Overhead Conveyor System Market.

The Above 500 Kg Capacity segment is the fastest-growing within the Overhead Conveyor System Market due to several key factors. Industries such as automotive, heavy manufacturing, and logistics warehouses require overhead conveyor systems with high load-bearing capacities to transport heavy components, machinery parts, and bulk materials efficiently. Above 500 Kg capacity overhead conveyor systems offer robust construction, specialized carriers, and powerful drive systems to handle heavy loads while maintaining smooth material flow and operational reliability. In addition, with the trend towards automation, Industry 4.0 technologies, and lean manufacturing practices, industries are investing in overhead conveyor systems with higher capacities to improve production throughput, reduce manual handling, and enhance overall efficiency. The strategic advantages of above 500 Kg capacity overhead conveyor systems in heavy-duty applications drive their rapid growth as the fastest-growing segment within the Overhead Conveyor System Market.

The Overhead Conveyor System industry's value chain encompasses diverse key stages involving raw material suppliers, system design and engineering, manufacturing, installation, and maintenance. Steel manufacturers like ArcelorMittal and plastic suppliers such as Dow Chemical Company provide essential materials for tracks, chains, and components, while electrical component suppliers like Schneider Electric contribute motors, sensors, and control systems. Companies like Daifuku Co., Ltd., Dematic, and SSI Schaefer lead the design, engineering, and manufacturing of complete conveyor systems, with integrators like Honeywell International Inc. and Emerson Electric Co. offering expertise in integrating conveyor systems with other material handling equipment.

Manufacturing involves transforming raw materials into various conveyor components, including tracks, chains, trolleys, and drives, often complemented by local metal fabrication shops for custom components. Installation and commissioning services are provided by system manufacturers and integrators, along with specialized installation contractors for large or complex projects. Maintenance and support services are offered by manufacturers themselves, as well as independent maintenance providers specializing in conveyor system upkeep and repairs.

The US Overhead Conveyor System Market serves diverse end-users such as automotive, logistics and e-commerce, food and beverage, and others, with conveyor capacities ranging from up to 50 Kg, 50 to 500 Kg, and above 500 Kg. These systems facilitate material handling and logistics operations, offering efficiency and automation in production and distribution processes. The market's growth is driven by industries seeking to streamline operations, improve productivity, and reduce manual labor costs through the adoption of overhead conveyor systems tailored to their specific capacity and application requirements.

TABLE OF CONTENTS

1 Introduction to 2024 Overhead Conveyor System Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Overhead Conveyor System Market Size Outlook, $ Million, 2021 to 2030

3.2 Overhead Conveyor System Market Outlook by Type, $ Million, 2021 to 2030

3.3 Overhead Conveyor System Market Outlook by Product, $ Million, 2021 to 2030

3.4 Overhead Conveyor System Market Outlook by Application, $ Million, 2021 to 2030

3.5 Overhead Conveyor System Market Outlook by Key Countries, $ Million, 2021 to 2030

4 Market Dynamics

4.1 Key Driving Forces of Overhead Conveyor System Industry

4.2 Key Market Trends in Overhead Conveyor System Industry

4.3 Potential Opportunities in Overhead Conveyor System Industry

4.4 Key Challenges in Overhead Conveyor System Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Overhead Conveyor System Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Overhead Conveyor System Market Outlook by Segments

7.1 Overhead Conveyor System Market Outlook by Segments, $ Million, 2021- 2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

8 North America Overhead Conveyor System Market Analysis and Outlook To 2030

8.1 Introduction to North America Overhead Conveyor System Markets in 2024

8.2 North America Overhead Conveyor System Market Size Outlook by Country, 2021-2030

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Overhead Conveyor System Market size Outlook by Segments, 2021-2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

9 Europe Overhead Conveyor System Market Analysis and Outlook To 2030

9.1 Introduction to Europe Overhead Conveyor System Markets in 2024

9.2 Europe Overhead Conveyor System Market Size Outlook by Country, 2021-2030

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Overhead Conveyor System Market Size Outlook by Segments, 2021-2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

10 Asia Pacific Overhead Conveyor System Market Analysis and Outlook To 2030

10.1 Introduction to Asia Pacific Overhead Conveyor System Markets in 2024

10.2 Asia Pacific Overhead Conveyor System Market Size Outlook by Country, 2021-2030

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Overhead Conveyor System Market size Outlook by Segments, 2021-2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

11 South America Overhead Conveyor System Market Analysis and Outlook To 2030

11.1 Introduction to South America Overhead Conveyor System Markets in 2024

11.2 South America Overhead Conveyor System Market Size Outlook by Country, 2021-2030

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Overhead Conveyor System Market size Outlook by Segments, 2021-2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

12 Middle East and Africa Overhead Conveyor System Market Analysis and Outlook To 2030

12.1 Introduction to Middle East and Africa Overhead Conveyor System Markets in 2024

12.2 Middle East and Africa Overhead Conveyor System Market Size Outlook by Country, 2021-2030

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Overhead Conveyor System Market size Outlook by Segments, 2021-2030

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

List of Companies

Aravali Engineers

ArSai Conve Systems

Bridgeveyor

Caldan Conveyor A. S.

Certina Holding

Chass Eng. Pvt Ltd

Daifuku Co. Ltd

Durr AG

Dynamic Conveyor Corp

FIVES SAS

KNAPP AG

MIDEA Group Co. Ltd

Niko Helm Hellas SA

OCS Overhead Conveyor System Ltd

OMH Group

Pacline Conveyors Inc

psb intralogistics GmbH

Railtechniek B.V.

Rapid Industries

Schonenberger Systeme GmbH

Siemens AG

SSI Schafer IT Solutions GmbH

United Engineering Industries

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By End-User

Automotive

Logistics and e-commerce

Food and beverage

Others

By Capacity

Up to 50 Kg

50 to 500 Kg

Above 500 Kg

Global Overhead Conveyor System Market is forecast to reach $16 Billion in 2030 from $11.1 Billion in 2024, registering a CAGR of 6.3% | Industry 4.0 integration

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Aravali Engineers, ArSai Conve Systems , Bridgeveyor, Caldan Conveyor A. S., Certina Holding, Chass Eng. Pvt Ltd, Daifuku Co. Ltd, Durr AG, Dynamic Conveyor Corp, FIVES SAS, KNAPP AG, MIDEA Group Co. Ltd, Niko Helm Hellas SA, OCS Overhead Conveyor System Ltd, OMH Group, Pacline Conveyors Inc, psb intralogistics GmbH, Railtechniek B.V., Rapid Industries, Schonenberger Systeme GmbH, Siemens AG, SSI Schafer IT Solutions GmbH, United Engineering Industries

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2030; Currency: Revenue (USD); Volume