The global Metallurgical Coke Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Grade (Low Ash, High Ash), By Application (Iron and Steel Making, Sugar Processing, Glass Manufacturing, Others).

Metallurgical coke, also known as met coke or blast furnace coke, is a critical raw material used in steelmaking and iron smelting processes in 2024. It is produced by carbonization of coal at high temperatures in the absence of air, resulting in a porous, high-carbon material with low impurity content and high strength. Metallurgical coke serves as a reducing agent and fuel in blast furnaces, where it reacts with iron ore and other raw materials to produce molten pig iron, the primary feedstock for steel production. Its high carbon content and low volatile matter make it ideal for generating the high temperatures required for iron smelting and refining processes. Met coke also provides structural support and permeability to the burden materials in the blast furnace, facilitating the flow of gases and liquids and ensuring efficient ironmaking operations. Additionally, metallurgical coke is used in foundries, ferroalloy production, and other metallurgical processes where high-quality carbon material is required. With the global steel industry experiencing steady growth and increasing demand for high-quality steel products in construction, automotive, and infrastructure sectors, the demand for metallurgical coke is expected to remain robust, supported by investments in steel production capacity expansions, infrastructure development, and technological advancements in ironmaking processes.

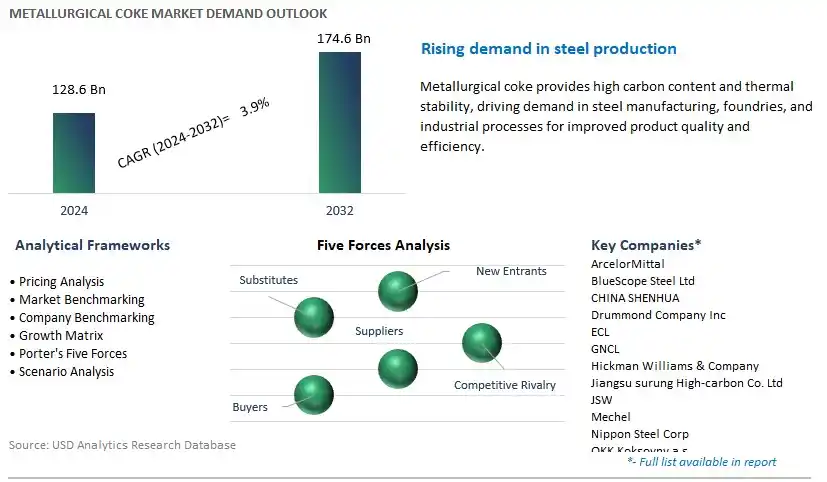

The market report analyses the leading companies in the industry including ArcelorMittal, BlueScope Steel Ltd, CHINA SHENHUA, Drummond Company Inc, ECL, GNCL, Hickman Williams & Company, Jiangsu surung High-carbon Co. Ltd, JSW, Mechel, Nippon Steel Corp, OKK Koksovny a.s., SunCoke Energy Inc, TECHNA-X BERHAD, YILDIRIM Group, and others.

A significant trend in the metallurgical coke market is the shift towards sustainable and low-carbon steel production. With increasing awareness of environmental concerns and climate change, there is a growing emphasis on reducing greenhouse gas emissions and adopting cleaner production methods in the steel industry. Metallurgical coke, a key raw material used in blast furnace ironmaking for steel production, is undergoing scrutiny due to its significant carbon footprint. As a result, there is a trend towards exploring alternative ironmaking technologies such as direct reduction processes and electric arc furnaces (EAFs) that reduce or eliminate the need for metallurgical coke. Additionally, efforts are being made to develop greener coke-making processes, such as using biomass-derived carbon sources or capturing and sequestering carbon emissions from coke production, to mitigate environmental impact. This trend towards sustainable steel production drives market evolution as steelmakers and coke producers seek to align with environmental regulations, customer preferences, and sustainability goals.

A key driver fueling the metallurgical coke market is the growth in steel demand and infrastructure development. Metallurgical coke is an essential component in the steelmaking process, providing the necessary carbon and heat to convert iron ore into molten iron in blast furnaces. With increasing urbanization, industrialization, and infrastructure projects worldwide, there is a continuous demand for steel to build bridges, roads, buildings, and various infrastructure facilities. Emerging economies, particularly in Asia-Pacific regions, are driving significant investments in infrastructure development, creating robust demand for steel and metallurgical coke. Additionally, sectors such as automotive, construction, and manufacturing contribute to steady demand for steel products, supporting the metallurgical coke market as a fundamental raw material in steel production.

A promising opportunity for the metallurgical coke market lies in the adoption of advanced coke-making technologies. With ongoing research and development efforts, there are opportunities to innovate and improve traditional coke-making processes to enhance efficiency, productivity, and environmental performance. Advanced technologies such as heat recovery systems, coke oven gas desulfurization, and by-product utilization systems can optimize energy utilization, reduce emissions, and maximize resource efficiency in coke production plants. Additionally, there is potential to integrate coke-making facilities with carbon capture and utilization (CCU) technologies to capture and utilize carbon emissions from coke ovens for beneficial applications such as enhanced oil recovery or synthetic fuel production. By embracing advanced coke-making technologies, coke producers can enhance their competitiveness, reduce operating costs, and minimize environmental impact, thus capitalizing on market opportunities while addressing sustainability challenges in the steel industry.

The largest segment within the metallurgical coke market is the low ash grade. Low ash grade metallurgical coke is preferred in various industrial processes, particularly in steel production, due to its superior quality and performance characteristics. Low ash coke is characterized by its low ash content, typically below a certain threshold, which ensures minimal impurities and contaminants during the combustion process. This results in cleaner and more efficient fuel combustion, leading to higher temperatures and better control over the metallurgical processes, such as iron ore smelting and steelmaking. Industries, especially steel manufacturers, rely on low ash coke to maintain consistent and high-quality steel production, as it contributes to improved furnace performance, reduced emissions, and higher yields. Additionally, low ash coke offers better mechanical strength and thermal stability compared to high ash grades, making it more suitable for use in modern, high-efficiency steelmaking technologies, such as blast furnaces and electric arc furnaces. The consistent demand for high-quality steel products worldwide ensures a steady market for low ash grade metallurgical coke, consolidating its position as the largest segment in the metallurgical coke market.

The fastest-growing segment within the metallurgical coke market is the iron and steel making application. In particular, the global demand for steel continues to rise steadily, driven by infrastructure development, construction projects, automotive manufacturing, and other industrial applications. Iron and steel production are fundamental to these sectors, and metallurgical coke plays a crucial role as a primary fuel and reducing agent in the steelmaking process. In addition, technological advancements in steelmaking processes, such as the adoption of more efficient blast furnace and electric arc furnace technologies, have increased the demand for high-quality metallurgical coke. Low ash content and consistent coke quality are essential for optimizing furnace performance and achieving desired steel quality parameters. Additionally, the growing emphasis on environmental sustainability and regulatory requirements to reduce carbon emissions in the steel industry further drive the demand for high-quality metallurgical coke, which produces fewer greenhouse gas emissions compared to alternative fuels. As a result, the iron and steel making application segment is experiencing rapid growth within the metallurgical coke market, fuelled by the expanding global steel industry and the need for cleaner and more efficient steel production processes.

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

ArcelorMittal

BlueScope Steel Ltd

CHINA SHENHUA

Drummond Company Inc

ECL

GNCL

Hickman Williams & Company

Jiangsu surung High-carbon Co. Ltd

JSW

Mechel

Nippon Steel Corp

OKK Koksovny a.s.

SunCoke Energy Inc

TECHNA-X BERHAD

YILDIRIM Group

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Metallurgical Coke Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Metallurgical Coke Market Size Outlook, $ Million, 2021 to 2032

3.2 Metallurgical Coke Market Outlook by Type, $ Million, 2021 to 2032

3.3 Metallurgical Coke Market Outlook by Product, $ Million, 2021 to 2032

3.4 Metallurgical Coke Market Outlook by Application, $ Million, 2021 to 2032

3.5 Metallurgical Coke Market Outlook by Key Countries, $ Million, 2021 to 2032

4 Market Dynamics

4.1 Key Driving Forces of Metallurgical Coke Industry

4.2 Key Market Trends in Metallurgical Coke Industry

4.3 Potential Opportunities in Metallurgical Coke Industry

4.4 Key Challenges in Metallurgical Coke Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Metallurgical Coke Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Metallurgical Coke Market Outlook by Segments

7.1 Metallurgical Coke Market Outlook by Segments, $ Million, 2021- 2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

8 North America Metallurgical Coke Market Analysis and Outlook To 2032

8.1 Introduction to North America Metallurgical Coke Markets in 2024

8.2 North America Metallurgical Coke Market Size Outlook by Country, 2021-2032

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Metallurgical Coke Market size Outlook by Segments, 2021-2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

9 Europe Metallurgical Coke Market Analysis and Outlook To 2032

9.1 Introduction to Europe Metallurgical Coke Markets in 2024

9.2 Europe Metallurgical Coke Market Size Outlook by Country, 2021-2032

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Metallurgical Coke Market Size Outlook by Segments, 2021-2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

10 Asia Pacific Metallurgical Coke Market Analysis and Outlook To 2032

10.1 Introduction to Asia Pacific Metallurgical Coke Markets in 2024

10.2 Asia Pacific Metallurgical Coke Market Size Outlook by Country, 2021-2032

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Metallurgical Coke Market size Outlook by Segments, 2021-2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

11 South America Metallurgical Coke Market Analysis and Outlook To 2032

11.1 Introduction to South America Metallurgical Coke Markets in 2024

11.2 South America Metallurgical Coke Market Size Outlook by Country, 2021-2032

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Metallurgical Coke Market size Outlook by Segments, 2021-2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

12 Middle East and Africa Metallurgical Coke Market Analysis and Outlook To 2032

12.1 Introduction to Middle East and Africa Metallurgical Coke Markets in 2024

12.2 Middle East and Africa Metallurgical Coke Market Size Outlook by Country, 2021-2032

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Metallurgical Coke Market size Outlook by Segments, 2021-2032

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

ArcelorMittal

BlueScope Steel Ltd

CHINA SHENHUA

Drummond Company Inc

ECL

GNCL

Hickman Williams & Company

Jiangsu surung High-carbon Co. Ltd

JSW

Mechel

Nippon Steel Corp

OKK Koksovny a.s.

SunCoke Energy Inc

TECHNA-X BERHAD

YILDIRIM Group

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Grade

Low Ash

High Ash

By Application

Iron and Steel Making

Sugar Processing

Glass Manufacturing

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Metallurgical Coke Market Size is valued at $128.6 Billion in 2024 and is forecast to register a growth rate (CAGR) of 3.9% to reach $174.6 Billion by 2032.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

ArcelorMittal, BlueScope Steel Ltd, CHINA SHENHUA, Drummond Company Inc, ECL, GNCL, Hickman Williams & Company, Jiangsu surung High-carbon Co. Ltd, JSW, Mechel, Nippon Steel Corp, OKK Koksovny a.s., SunCoke Energy Inc, TECHNA-X BERHAD, YILDIRIM Group

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2032; Currency: Revenue (USD); Volume