The global Hydrocarbon Fire Intumescent Coating Services Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Type (Emulsion, Solvent, Others), By End-User (Chemicals, Oil and Gas, Metals and Mining, Lime and Cement, Pulp and Paper, Others).

Hydrocarbon fire intumescent coating services play a crucial role in passive fire protection for industrial facilities, offshore platforms, and infrastructure assets by providing fire resistance and thermal insulation to structural components, vessels, and equipment exposed to hydrocarbon fires. One key trend shaping the future of hydrocarbon fire intumescent coating services is the development of advanced coating formulations, application techniques, and testing methodologies to enhance fire performance, durability, and regulatory compliance while reducing application time and environmental impact. Coating manufacturers and service providers are innovating new intumescent coatings with improved adhesion, expansion properties, and fire resistance ratings, enabling thinner coating thicknesses and lighter weight solutions without compromising fire protection standards. Additionally, advancements in surface preparation methods, spray equipment, and robotic application technologies are optimizing coating coverage, uniformity, and quality control, ensuring consistent and reliable fire protection for complex geometries and large-scale assets. Moreover, the integration of fire modeling software, fire testing facilities, and performance-based design approaches is enabling predictive modeling and optimization of fire protection strategies, ensuring compliance with industry standards and regulatory requirements. As industries prioritize safety, asset protection, and operational continuity in high-risk environments, the hydrocarbon fire intumescent coating services industry is poised for innovation and growth, with opportunities for collaboration, technology transfer, and market expansion to meet the evolving needs of asset owners, insurers, and regulatory authorities.

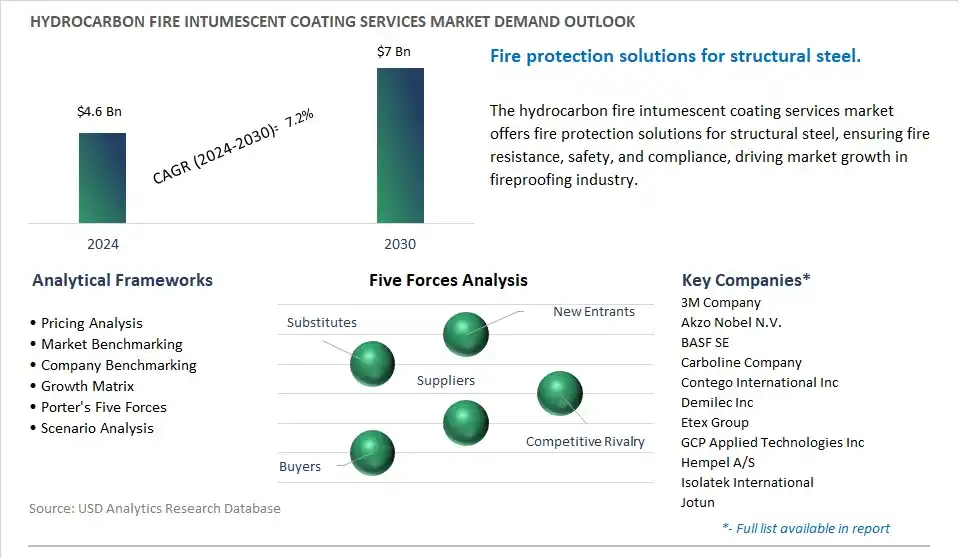

The market report analyses the leading companies in the industry including 3M Company, Akzo Nobel N.V., BASF SE, Carboline Company, Contego International Inc, Demilec Inc, Etex Group, GCP Applied Technologies Inc, Hempel A/S, Isolatek International, Jotun, Kansai Paint Co. Ltd, PPG Industries Inc, The Sherwin-Williams Company.

A prominent trend in the market for Hydrocarbon Fire Intumescent Coating Services is the increasing focus on fire safety regulations and building codes in construction and industrial sectors. With heightened awareness of fire hazards and the need to protect infrastructure and assets from fire-related risks, there is a growing emphasis on implementing passive fire protection measures, including the application of intumescent coatings. These coatings expand and form insulating char layers when exposed to high temperatures, providing fire resistance to structural steel and other substrates. This is driven by stricter building codes, insurance requirements, and safety standards aimed at mitigating the impact of fires on human life, property, and the environment, leading to increased demand for hydrocarbon fire intumescent coating services in commercial, residential, and industrial construction projects worldwide.

The market for Hydrocarbon Fire Intumescent Coating Services is being driven by the growth in industrial and infrastructure development projects that require fire protection solutions for critical assets and facilities. As industries expand and infrastructure investments increase, there is a need for passive fire protection systems that can safeguard structural elements and equipment from the devastating effects of fire events. Hydrocarbon fire intumescent coatings offer a cost-effective and efficient solution for enhancing fire resistance in industrial facilities, petrochemical plants, refineries, and offshore installations, where the risk of hydrocarbon fires is particularly high. Factors such as urbanization, industrialization, and the expansion of energy and transportation infrastructure drive investments in fire protection measures, fueling market growth and demand for hydrocarbon fire intumescent coating services in construction and industrial sectors.

An exciting opportunity within the market for Hydrocarbon Fire Intumescent Coating Services lies in the expansion into retrofit and maintenance markets, where there is a growing demand for refurbishment and upgrade projects to enhance fire safety in existing buildings and structures. Companies can explore opportunities to provide coating services for retrofitting fire protection systems in aging infrastructure, commercial buildings, and industrial facilities that do not meet current fire safety standards. Additionally, there is potential to offer maintenance and inspection services for existing intumescent coatings to ensure their effectiveness and compliance with regulatory requirements over time. By leveraging their expertise in fire protection engineering, coating application, and building maintenance, companies can capitalize on the growing demand for retrofit and maintenance solutions and position themselves as trusted partners in enhancing fire safety and protecting assets in the built environment, driving growth and expansion in the hydrocarbon fire intumescent coating services market.

The Hydrocarbon Fire Intumescent Coating Services Market operates through a series of specialized stages, with distinct companies contributing to the final fire protection solution. Intumescent coating manufacturers including PPG Industries and Hempel produce base coatings containing fire-retardant chemicals, while raw material suppliers including Albemarle Corporation and Clariant provide specific components for these formulations. Project design and specification involve fireproofing contractors including Walbridge and Balfour Beatty, alongside fire safety consultants including WSP and Arup, which recommend suitable fire protection solutions. Surface preparation contractors specialize in preparing surfaces for coating application, ensuring proper adhesion and performance.

During coating application, fireproofing contractors and painting contractors with certified applicators ensure the coatings are applied correctly. Inspection and quality control are handled by independent agencies including SGS and Bureau Veritas, verifying proper application according to project specifications. Further, construction companies and building owners/operators are the end users responsible for ensuring compliance with fire safety regulations and adequate fire protection measures.

The largest segment in the Hydrocarbon Fire Intumescent Coating Services Market is the Solvent type segment. This dominance is primarily due to diverse key factors. Solvent-based intumescent coatings are widely preferred for hydrocarbon fire protection applications due to their robust fire resistance properties, durability, and ease of application. These coatings contain a solvent carrier, which evaporates during the curing process, leaving behind a protective layer of char that insulates the underlying substrate from heat and flames. Additionally, solvent-based intumescent coatings offer excellent adhesion to various substrates, including steel, concrete, and wood, making them suitable for a wide range of industrial and commercial applications. In addition, solvent-based formulations provide superior performance in harsh environments with exposure to hydrocarbon fires, such as petrochemical plants, refineries, offshore platforms, and industrial facilities handling flammable materials. Further, solvent-based intumescent coatings are often preferred for their versatility and compatibility with different surface conditions, including high humidity, temperature variations, and outdoor exposure. Overall, the Solvent type segment holds the largest share in the Hydrocarbon Fire Intumescent Coating Services Market due to the superior fire protection properties, durability, and versatility of solvent-based intumescent coatings in hydrocarbon fire protection applications.

The fastest-growing segment in the Hydrocarbon Fire Intumescent Coating Services Market is the Oil and Gas end-user segment. This growth is primarily due to diverse key factors. Firstly, the oil and gas industry operates in environments where the risk of hydrocarbon fires is particularly high, such as offshore platforms, refineries, storage tanks, and pipelines. Intumescent coatings play a crucial role in protecting critical infrastructure and equipment from the devastating effects of fire by providing passive fire protection. Additionally, the increasing investments in oil and gas exploration, production, and refining activities worldwide drive the demand for advanced fire protection solutions, including intumescent coatings. In addition, stringent safety regulations and standards governing fire protection and prevention in the oil and gas industry further accelerate the adoption of intumescent coating services. Further, the growing awareness of the importance of fire safety, risk mitigation, and asset protection in the oil and gas sector drives the demand for specialized coatings and services tailored to the industry's unique needs. Overall, the Oil and Gas end-user segment is experiencing rapid growth in the Hydrocarbon Fire Intumescent Coating Services Market due to the industry's high susceptibility to hydrocarbon fires, regulatory requirements, and the increasing focus on safety and asset protection.

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

3M Company

Akzo Nobel N.V.

BASF SE

Carboline Company

Contego International Inc

Demilec Inc

Etex Group

GCP Applied Technologies Inc

Hempel A/S

Isolatek International

Jotun

Kansai Paint Co. Ltd

PPG Industries Inc

The Sherwin-Williams Company

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Hydrocarbon Fire Intumescent Coating Services Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Hydrocarbon Fire Intumescent Coating Services Market Size Outlook, $ Million, 2021 to 2030

3.2 Hydrocarbon Fire Intumescent Coating Services Market Outlook by Type, $ Million, 2021 to 2030

3.3 Hydrocarbon Fire Intumescent Coating Services Market Outlook by Product, $ Million, 2021 to 2030

3.4 Hydrocarbon Fire Intumescent Coating Services Market Outlook by Application, $ Million, 2021 to 2030

3.5 Hydrocarbon Fire Intumescent Coating Services Market Outlook by Key Countries, $ Million, 2021 to 2030

4 Market Dynamics

4.1 Key Driving Forces of Hydrocarbon Fire Intumescent Coating Services Industry

4.2 Key Market Trends in Hydrocarbon Fire Intumescent Coating Services Industry

4.3 Potential Opportunities in Hydrocarbon Fire Intumescent Coating Services Industry

4.4 Key Challenges in Hydrocarbon Fire Intumescent Coating Services Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Hydrocarbon Fire Intumescent Coating Services Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Hydrocarbon Fire Intumescent Coating Services Market Outlook by Segments

7.1 Hydrocarbon Fire Intumescent Coating Services Market Outlook by Segments, $ Million, 2021- 2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

8 North America Hydrocarbon Fire Intumescent Coating Services Market Analysis and Outlook To 2030

8.1 Introduction to North America Hydrocarbon Fire Intumescent Coating Services Markets in 2024

8.2 North America Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Country, 2021-2030

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Hydrocarbon Fire Intumescent Coating Services Market size Outlook by Segments, 2021-2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

9 Europe Hydrocarbon Fire Intumescent Coating Services Market Analysis and Outlook To 2030

9.1 Introduction to Europe Hydrocarbon Fire Intumescent Coating Services Markets in 2024

9.2 Europe Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Country, 2021-2030

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Segments, 2021-2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

10 Asia Pacific Hydrocarbon Fire Intumescent Coating Services Market Analysis and Outlook To 2030

10.1 Introduction to Asia Pacific Hydrocarbon Fire Intumescent Coating Services Markets in 2024

10.2 Asia Pacific Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Country, 2021-2030

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Hydrocarbon Fire Intumescent Coating Services Market size Outlook by Segments, 2021-2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

11 South America Hydrocarbon Fire Intumescent Coating Services Market Analysis and Outlook To 2030

11.1 Introduction to South America Hydrocarbon Fire Intumescent Coating Services Markets in 2024

11.2 South America Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Country, 2021-2030

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Hydrocarbon Fire Intumescent Coating Services Market size Outlook by Segments, 2021-2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

12 Middle East and Africa Hydrocarbon Fire Intumescent Coating Services Market Analysis and Outlook To 2030

12.1 Introduction to Middle East and Africa Hydrocarbon Fire Intumescent Coating Services Markets in 2024

12.2 Middle East and Africa Hydrocarbon Fire Intumescent Coating Services Market Size Outlook by Country, 2021-2030

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Hydrocarbon Fire Intumescent Coating Services Market size Outlook by Segments, 2021-2030

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

3M Company

Akzo Nobel N.V.

BASF SE

Carboline Company

Contego International Inc

Demilec Inc

Etex Group

GCP Applied Technologies Inc

Hempel A/S

Isolatek International

Jotun

Kansai Paint Co. Ltd

PPG Industries Inc

The Sherwin-Williams Company

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Type

Emulsion

Solvent

Others

By End-User

Chemicals

Oil and Gas

Metals and Mining

Lime and Cement

Pulp and Paper

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Hydrocarbon Fire Intumescent Coating Services is forecast to reach $7 Billion in 2030 from $4.6 Billion in 2024, registering a CAGR of 7.2% over the outlook period

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

3M Company, Akzo Nobel N.V., BASF SE, Carboline Company, Contego International Inc, Demilec Inc, Etex Group, GCP Applied Technologies Inc, Hempel A/S, Isolatek International, Jotun, Kansai Paint Co. Ltd, PPG Industries Inc, The Sherwin-Williams Company

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2030; Currency: Revenue (USD); Volume