The global High-Temperature 3D Printing Plastics Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Type (PEEK, PEI, PEKK, PPSU, Others), By End-User (Automotive, Aerospace & Defense, Electrical & Electronics, Healthcare, Consumer Goods, Others).

High-temperature 3D printing plastics, such as polyetheretherketone (PEEK), polyetherimide (PEI), and polyphenylsulfone (PPSU), are advanced engineering thermoplastics used in additive manufacturing processes to produce functional prototypes, tooling, and end-use parts for aerospace, automotive, medical, and industrial applications. One key trend shaping the future of high-temperature 3D printing plastics is the development of new polymer formulations, processing parameters, and printing technologies to expand the range of printable materials and improve print quality, part performance, and process reliability. Material suppliers and 3D printer manufacturers are collaborating to develop high-temperature filaments, powders, and resins with enhanced thermal stability, mechanical strength, and chemical resistance, enabling the production of parts capable of withstanding demanding operating conditions such as high temperatures, corrosive environments, and mechanical stress. Additionally, advancements in 3D printing hardware, software, and post-processing techniques are improving printing resolution, surface finish, and dimensional accuracy of high-temperature plastic parts, enabling rapid prototyping, customization, and on-demand production of complex components with reduced lead times and material waste. Moreover, the integration of digital design tools, simulation software, and material characterization methods is enabling predictive modeling and optimization of part performance, ensuring compliance with regulatory requirements and industry standards. As industries embrace additive manufacturing for lightweighting, design optimization, and customization, the high-temperature 3D printing plastics industry is poised for innovation and growth, with opportunities for collaboration, material development, and market expansion to meet the evolving needs of customers and regulatory requirements.

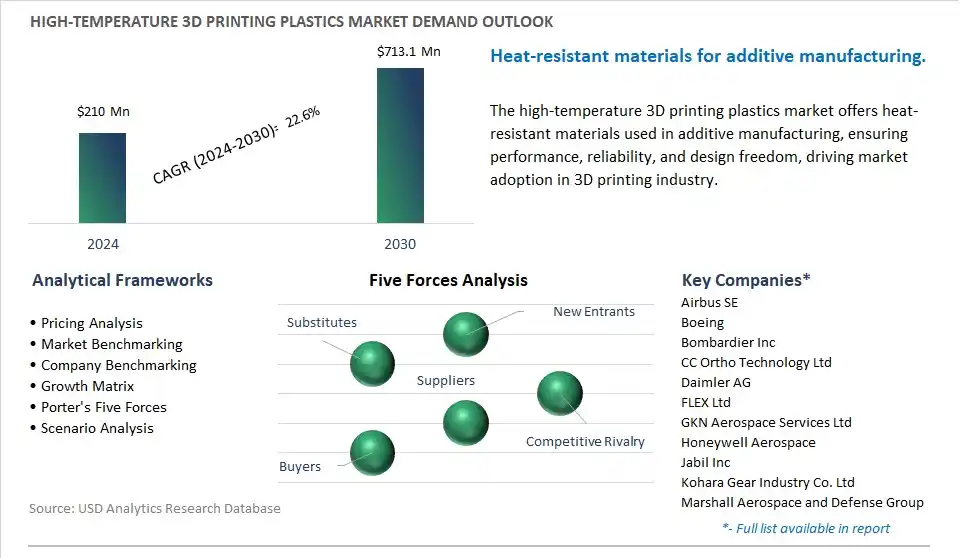

The market report analyses the leading companies in the industry including Airbus SE, Boeing, Bombardier Inc, CC Ortho Technology Ltd, Daimler AG, FLEX Ltd, GKN Aerospace Services Ltd, Honeywell Aerospace, Jabil Inc, Kohara Gear Industry Co. Ltd, Marshall Aerospace and Defense Group, National Dentex Corp, Robert Bosch GmbH, TE Connectivity Ltd, Trelleborg AB.

A prominent trend in the market for High-Temperature 3D Printing Plastics is the surge in demand for parts that can withstand high temperatures in industrial applications. Industries such as aerospace, automotive, and electronics require components capable of withstanding extreme heat conditions without compromising on performance or integrity. High-temperature 3D printing plastics offer a viable solution by providing parts with thermal stability, chemical resistance, and mechanical strength, allowing manufacturers to produce complex geometries for critical applications. This is driven by the need for lightweight, durable, and heat-resistant materials in high-temperature environments, leading to increased adoption of high-temperature 3D printing plastics across various industrial sectors.

The market for High-Temperature 3D Printing Plastics is being driven by technological advancements in 3D printing technology and material development that enable the production of parts capable of withstanding elevated temperatures. Manufacturers of 3D printers and plastic materials are continuously innovating to improve print quality, accuracy, and reliability, while also expanding the range of materials suitable for high-temperature applications. Factors such as the demand for customized parts, the need for rapid prototyping and production, and the need for cost-effective manufacturing solutions drive investments in 3D printing technology and material science. This driver is further fueled by collaborations between industry and academia, government funding for research and development, and partnerships with end-users to address specific application challenges and performance requirements, driving market growth and innovation in high-temperature 3D printing plastics.

An exciting opportunity within the market for High-Temperature 3D Printing Plastics lies in the expansion into aerospace and defense applications that demand parts with exceptional thermal and mechanical properties. Companies can explore opportunities to provide high-temperature 3D printing plastics for manufacturing components such as engine parts, heat exchangers, and electronic enclosures, where heat resistance, lightweight, and design flexibility are critical requirements. Additionally, there is potential to develop specialized materials for niche applications such as space exploration, missile systems, and aircraft interiors, where high-temperature 3D printing plastics offer advantages such as reduced lead times, cost savings, and performance enhancements. By leveraging their expertise in material science, additive manufacturing technologies, and industry partnerships, companies can capitalize on the growing demand for high-temperature 3D printing plastics and position themselves as leaders in providing advanced materials solutions for aerospace and defense applications.

The high-temperature 3D printing plastics market operates through a focused Market Ecosystem, with key players contributing at various stages. Raw material suppliers including Dow Chemical and BASF provide high-performance polymer precursors and specialty polymers tailored for high-temperature filaments, with materials sourced from oil & gas companies including ExxonMobil. Polymer production involves specialty chemical companies including Arkema, Solvay, and Victrex plc manufacturing high-temperature resistant polymers, while integrated oil & gas companies including Chevron Phillips Chemical also produce certain high-temperature polymers. Filament or pellet manufacturing is executed by polymer producers and specialty filament/pellet producers including Stratasys and Ultimaker, manufacturing filaments and pellets specifically for high-temperature 3D printing applications.

Distribution channels managed by 3D printing filament distributors including MatterHackers and Proto Labs ensure the availability of filaments for various printing technologies, including high-temperature options, while plastics distributors carry pellets of high-temperature plastics for industrial use. End-users across industries including aerospace & defense, automotive, oil & gas, and medical devices benefit from the utilization of high-temperature 3D printing plastics for applications requiring high heat resistance. The plastics find applications in aircraft parts, engine components, under-the-hood automotive parts, oil & gas components, and medical equipment including sterilization trays, driving innovation and efficiency in key sectors.

The largest segment in the High-Temperature 3D Printing Plastics Market is the PEEK (Polyether Ether Ketone) segment. This dominance is attributed to diverse key factors. PEEK is widely recognized for its exceptional thermal stability, chemical resistance, and mechanical properties, making it an ideal choice for high-temperature applications in industries such as aerospace, automotive, healthcare, and electronics. In the 3D printing realm, PEEK offers unique advantages, including high heat deflection temperature, excellent dimensional stability, and ease of processing, making it well-suited for producing functional prototypes, tooling, and end-use parts that require high-temperature resistance and mechanical performance. Additionally, the growing adoption of additive manufacturing technologies for producing complex geometries and customized components further drives the demand for high-temperature 3D printing plastics like PEEK. In addition, ongoing research and development efforts focused on enhancing PEEK's printability, mechanical properties, and affordability contribute to its widespread adoption and dominance in the High-Temperature 3D Printing Plastics Market. Overall, the PEEK segment holds the largest share due to its superior properties and versatility, making it a preferred choice for high-temperature 3D printing applications across various industries.

The fastest-growing segment in the High-Temperature 3D Printing Plastics Market is the Aerospace and Defense end-user segment. This growth can be attributed to diverse key factors. Firstly, the aerospace and defense industries have stringent requirements for lightweight, high-performance materials that can withstand extreme temperatures and harsh operating conditions. High-temperature 3D printing plastics offer unique advantages in these sectors, providing the ability to produce complex geometries and lightweight components with excellent mechanical properties and temperature resistance. Additionally, the adoption of additive manufacturing technologies in aerospace and defense enables the production of customized parts, rapid prototyping, and on-demand manufacturing, driving the demand for high-temperature 3D printing plastics. In addition, ongoing advancements in materials science and additive manufacturing processes are continuously improving the performance and capabilities of high-temperature plastics, further fueling their adoption in aerospace and defense applications. Further, the increasing focus on sustainability and cost-effectiveness in aerospace and defense manufacturing encourages the use of additive manufacturing technologies and high-temperature plastics to optimize production processes and reduce waste. Overall, the Aerospace and Defense end-user segment is experiencing rapid growth in the High-Temperature 3D Printing Plastics Market due to the sectors' demanding requirements, technological advancements, and the benefits offered by additive manufacturing for producing high-performance components.

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

Airbus SE

Boeing

Bombardier Inc

CC Ortho Technology Ltd

Daimler AG

FLEX Ltd

GKN Aerospace Services Ltd

Honeywell Aerospace

Jabil Inc

Kohara Gear Industry Co. Ltd

Marshall Aerospace and Defense Group

National Dentex Corp

Robert Bosch GmbH

TE Connectivity Ltd

Trelleborg AB

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 High-Temperature 3D Printing Plastics Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global High-Temperature 3D Printing Plastics Market Size Outlook, $ Million, 2021 to 2030

3.2 High-Temperature 3D Printing Plastics Market Outlook by Type, $ Million, 2021 to 2030

3.3 High-Temperature 3D Printing Plastics Market Outlook by Product, $ Million, 2021 to 2030

3.4 High-Temperature 3D Printing Plastics Market Outlook by Application, $ Million, 2021 to 2030

3.5 High-Temperature 3D Printing Plastics Market Outlook by Key Countries, $ Million, 2021 to 2030

4 Market Dynamics

4.1 Key Driving Forces of High-Temperature 3D Printing Plastics Industry

4.2 Key Market Trends in High-Temperature 3D Printing Plastics Industry

4.3 Potential Opportunities in High-Temperature 3D Printing Plastics Industry

4.4 Key Challenges in High-Temperature 3D Printing Plastics Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global High-Temperature 3D Printing Plastics Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global High-Temperature 3D Printing Plastics Market Outlook by Segments

7.1 High-Temperature 3D Printing Plastics Market Outlook by Segments, $ Million, 2021- 2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

8 North America High-Temperature 3D Printing Plastics Market Analysis and Outlook To 2030

8.1 Introduction to North America High-Temperature 3D Printing Plastics Markets in 2024

8.2 North America High-Temperature 3D Printing Plastics Market Size Outlook by Country, 2021-2030

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America High-Temperature 3D Printing Plastics Market size Outlook by Segments, 2021-2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

9 Europe High-Temperature 3D Printing Plastics Market Analysis and Outlook To 2030

9.1 Introduction to Europe High-Temperature 3D Printing Plastics Markets in 2024

9.2 Europe High-Temperature 3D Printing Plastics Market Size Outlook by Country, 2021-2030

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe High-Temperature 3D Printing Plastics Market Size Outlook by Segments, 2021-2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

10 Asia Pacific High-Temperature 3D Printing Plastics Market Analysis and Outlook To 2030

10.1 Introduction to Asia Pacific High-Temperature 3D Printing Plastics Markets in 2024

10.2 Asia Pacific High-Temperature 3D Printing Plastics Market Size Outlook by Country, 2021-2030

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific High-Temperature 3D Printing Plastics Market size Outlook by Segments, 2021-2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

11 South America High-Temperature 3D Printing Plastics Market Analysis and Outlook To 2030

11.1 Introduction to South America High-Temperature 3D Printing Plastics Markets in 2024

11.2 South America High-Temperature 3D Printing Plastics Market Size Outlook by Country, 2021-2030

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America High-Temperature 3D Printing Plastics Market size Outlook by Segments, 2021-2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

12 Middle East and Africa High-Temperature 3D Printing Plastics Market Analysis and Outlook To 2030

12.1 Introduction to Middle East and Africa High-Temperature 3D Printing Plastics Markets in 2024

12.2 Middle East and Africa High-Temperature 3D Printing Plastics Market Size Outlook by Country, 2021-2030

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa High-Temperature 3D Printing Plastics Market size Outlook by Segments, 2021-2030

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

Airbus SE

Boeing

Bombardier Inc

CC Ortho Technology Ltd

Daimler AG

FLEX Ltd

GKN Aerospace Services Ltd

Honeywell Aerospace

Jabil Inc

Kohara Gear Industry Co. Ltd

Marshall Aerospace and Defense Group

National Dentex Corp

Robert Bosch GmbH

TE Connectivity Ltd

Trelleborg AB

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Type

PEEK

PEI

PEKK

PPSU

Others

By End-User

Automotive

Aerospace & Defense

Electrical & Electronics

Healthcare

Consumer Goods

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global High-Temperature 3D Printing Plastics is forecast to reach $713.1 Million in 2030 from $210 Million in 2024, registering a CAGR of 22.6% over the outlook period

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Airbus SE, Boeing, Bombardier Inc, CC Ortho Technology Ltd, Daimler AG, FLEX Ltd, GKN Aerospace Services Ltd, Honeywell Aerospace, Jabil Inc, Kohara Gear Industry Co. Ltd, Marshall Aerospace and Defense Group, National Dentex Corp, Robert Bosch GmbH, TE Connectivity Ltd, Trelleborg AB

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2030; Currency: Revenue (USD); Volume