The global Glass Prepreg Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By Resin (Thermosetting, Thermoplastic), By End-User (Aerospace and Defense, Automotive, Wind Turbine, Sports and Leisure, Others).

Glass prepreg is a composite material consisting of glass fiber reinforcement impregnated with a thermosetting resin matrix, typically epoxy resin, in 2024. Prepregs are partially cured under controlled conditions and then stored at low temperatures to prevent further curing until they are ready for use. Glass prepregs offer excellent mechanical properties, dimensional stability, and chemical resistance, making them suitable for various structural and high-performance applications in aerospace, automotive, marine, and sporting goods industries. Glass prepregs are available in various forms, including rolls, sheets, tapes, and fabrics, allowing for customization and ease of handling during fabrication. They are used to manufacture components such as aircraft fuselages, automotive body panels, boat hulls, sporting equipment, and wind turbine blades, where lightweight, high-strength, and corrosion-resistant materials are required. Glass prepregs offer advantages such as precise fiber alignment, consistent resin distribution, and excellent fatigue resistance, resulting in superior performance and reliability of finished parts. With their versatility, durability, and efficiency in manufacturing complex shapes, glass prepregs to be a preferred choice for engineers and designers seeking lightweight and high-performance solutions for demanding applications.

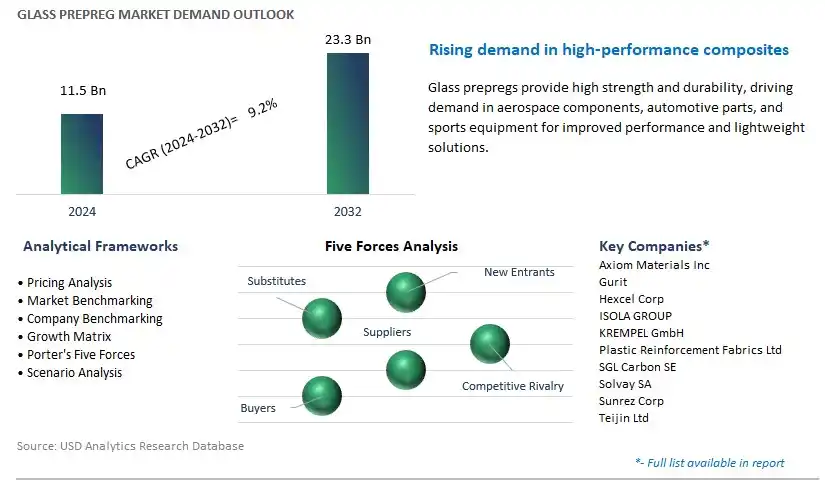

The market report analyses the leading companies in the industry including Axiom Materials Inc, Gurit, Hexcel Corp, ISOLA GROUP, KREMPEL GmbH, Plastic Reinforcement Fabrics Ltd, SGL Carbon SE, Solvay SA, Sunrez Corp, Teijin Ltd, and others.

A prominent trend in the glass prepreg market is the increasing demand for lightweight and high-performance materials. With industries such as aerospace, automotive, wind energy, and sports and leisure seeking solutions to reduce weight, improve fuel efficiency, and enhance product performance, there is a growing preference for glass prepregs due to their excellent strength-to-weight ratio and versatility. This trend is driven by the need to meet stringent regulatory standards for emissions, safety, and performance, as well as the desire among consumers for products that offer superior durability, reliability, and sustainability. As industries embrace lightweighting strategies and seek innovative materials to address these challenges, the demand for glass prepregs as essential components in composite manufacturing is expected to grow, driving market expansion and innovation in prepreg technologies.

A key driver propelling the growth of the glass prepreg market is the growth in aerospace and wind energy industries. Glass prepregs are widely used in aerospace applications such as aircraft structures, interiors, and components, where they offer advantages such as high strength, stiffness, fatigue resistance, and fire retardancy. Additionally, glass prepregs find applications in wind turbine blades, where they provide durability, corrosion resistance, and aerodynamic performance under harsh environmental conditions. With increasing demand for air travel, renewable energy sources, and sustainable transportation solutions, there is significant demand for glass prepregs that offer lightweight, durable, and cost-effective solutions for aerospace and wind energy applications. As aerospace manufacturers and wind energy developers continue to invest in research and development, technology advancements, and production scale-up, the demand for glass prepregs as essential materials in composite manufacturing is expected to escalate, driving market growth and adoption in these industries.

An opportunity for growth within the glass prepreg market lies in diversification into new industries and applications beyond traditional uses in aerospace and wind energy. While glass prepregs are widely used in these industries for structural components and turbine blades, there are untapped opportunities in sectors such as automotive, marine, construction, and sporting goods that demand lightweight, durable, and customizable materials with specific properties and functionalities. For example, glass prepregs find applications in automotive body panels, chassis components, and interior parts, where properties such as impact resistance, vibration damping, and design flexibility are critical for vehicle performance and aesthetics. Similarly, glass prepregs are used in marine vessels, yachts, and recreational vehicles for hulls, decks, and structural elements, where properties such as corrosion resistance, buoyancy, and hydrodynamics are essential for marine performance and durability. By exploring these new market segments and developing tailored glass prepreg solutions to address specific needs and requirements, manufacturers can diversify their product portfolios, capture new revenue streams, and drive innovation in composite materials. Moreover, as industries continue to prioritize lightweighting, sustainability, and performance, there is potential for collaboration and partnership to unlock novel applications and address emerging market demands effectively.

Thermosetting resin is the largest segment in the Glass Prepreg Market. In particular, thermosetting resins, such as epoxy and phenolic, offer excellent mechanical properties, chemical resistance, and thermal stability, making them widely preferred for high-performance composite applications. Thermosetting resins undergo irreversible curing reactions when exposed to heat, forming cross-linked polymer networks that provide exceptional strength and stiffness to glass prepreg materials. Additionally, thermosetting resin-based glass prepregs exhibit excellent adhesion to various substrates, allowing for the fabrication of complex-shaped components with uniform fiber distribution and minimal void content. Moreover, the superior mechanical properties and versatility of thermosetting resin-based glass prepregs make them suitable for diverse end-use applications, including aerospace, automotive, wind energy, and sporting goods. As a result, thermosetting resin segment maintains its dominance in the Glass Prepreg Market, offering manufacturers and end-users reliable and high-performance composite solutions for demanding applications.

The Wind Turbine segment is the fastest-growing segment in the Glass Prepreg Market. In particular, the global shift towards renewable energy sources, coupled with the increasing demand for clean and sustainable power generation, has fuelled significant investments in wind energy infrastructure worldwide. Glass prepreg materials play a vital role in the manufacturing of wind turbine blades, offering exceptional strength-to-weight ratio, fatigue resistance, and durability to withstand harsh operating conditions. Additionally, the trend towards larger and more efficient wind turbines necessitates the use of advanced composite materials such as glass prepregs to optimize blade design and performance. Moreover, the ongoing technological advancements in wind turbine blade manufacturing processes, including automated layup techniques and resin infusion methods, further enhance the adoption of glass prepreg materials in the wind energy industry. As a result, the wind turbine segment presents lucrative growth opportunities for manufacturers and suppliers in the Glass Prepreg Market, poised to meet the increasing demand for high-performance composite materials in the renewable energy sector.

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Axiom Materials Inc

Gurit

Hexcel Corp

ISOLA GROUP

KREMPEL GmbH

Plastic Reinforcement Fabrics Ltd

SGL Carbon SE

Solvay SA

Sunrez Corp

Teijin Ltd

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Glass Prepreg Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Glass Prepreg Market Size Outlook, $ Million, 2021 to 2032

3.2 Glass Prepreg Market Outlook by Type, $ Million, 2021 to 2032

3.3 Glass Prepreg Market Outlook by Product, $ Million, 2021 to 2032

3.4 Glass Prepreg Market Outlook by Application, $ Million, 2021 to 2032

3.5 Glass Prepreg Market Outlook by Key Countries, $ Million, 2021 to 2032

4 Market Dynamics

4.1 Key Driving Forces of Glass Prepreg Industry

4.2 Key Market Trends in Glass Prepreg Industry

4.3 Potential Opportunities in Glass Prepreg Industry

4.4 Key Challenges in Glass Prepreg Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Glass Prepreg Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Glass Prepreg Market Outlook by Segments

7.1 Glass Prepreg Market Outlook by Segments, $ Million, 2021- 2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

8 North America Glass Prepreg Market Analysis and Outlook To 2032

8.1 Introduction to North America Glass Prepreg Markets in 2024

8.2 North America Glass Prepreg Market Size Outlook by Country, 2021-2032

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Glass Prepreg Market size Outlook by Segments, 2021-2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

9 Europe Glass Prepreg Market Analysis and Outlook To 2032

9.1 Introduction to Europe Glass Prepreg Markets in 2024

9.2 Europe Glass Prepreg Market Size Outlook by Country, 2021-2032

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Glass Prepreg Market Size Outlook by Segments, 2021-2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

10 Asia Pacific Glass Prepreg Market Analysis and Outlook To 2032

10.1 Introduction to Asia Pacific Glass Prepreg Markets in 2024

10.2 Asia Pacific Glass Prepreg Market Size Outlook by Country, 2021-2032

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Glass Prepreg Market size Outlook by Segments, 2021-2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

11 South America Glass Prepreg Market Analysis and Outlook To 2032

11.1 Introduction to South America Glass Prepreg Markets in 2024

11.2 South America Glass Prepreg Market Size Outlook by Country, 2021-2032

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Glass Prepreg Market size Outlook by Segments, 2021-2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

12 Middle East and Africa Glass Prepreg Market Analysis and Outlook To 2032

12.1 Introduction to Middle East and Africa Glass Prepreg Markets in 2024

12.2 Middle East and Africa Glass Prepreg Market Size Outlook by Country, 2021-2032

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Glass Prepreg Market size Outlook by Segments, 2021-2032

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

Axiom Materials Inc

Gurit

Hexcel Corp

ISOLA GROUP

KREMPEL GmbH

Plastic Reinforcement Fabrics Ltd

SGL Carbon SE

Solvay SA

Sunrez Corp

Teijin Ltd

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By Resin

Thermosetting

Thermoplastic

By End-User

Aerospace and Defense

Automotive

Wind Turbine

Sports and Leisure

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Glass Prepreg Market Size is valued at $11.5 Billion in 2024 and is forecast to register a growth rate (CAGR) of 9.2% to reach $23.3 Billion by 2032.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Axiom Materials Inc, Gurit, Hexcel Corp, ISOLA GROUP, KREMPEL GmbH, Plastic Reinforcement Fabrics Ltd, SGL Carbon SE, Solvay SA, Sunrez Corp, Teijin Ltd

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2032; Currency: Revenue (USD); Volume