The global Electron Beam Curable Coating Market Study analyzes and forecasts the market size across 6 regions and 24 countries for diverse segments -By End-User (Aerospace, Electrical and Electronics, Automotive, Packaging, Others), By Type (Anti-reflection, Transparent Electrodes, Filter Coating, Others).

Electron beam (EB) curable coatings are environmentally friendly coatings that cure rapidly upon exposure to high-energy electron beams in 2024. These coatings are formulated with reactive monomers, oligomers, and additives that polymerize and crosslink when irradiated with electron beams, resulting in a durable and chemically resistant finish. EB curing offers several advantages over conventional curing methods, including faster curing times, lower energy consumption, and reduced volatile organic compound (VOC) emissions. EB curable coatings are used in various industrial applications, including printing, packaging, automotive, and electronics, where they provide high-performance finishes with excellent adhesion, scratch resistance, and color stability. They are applied as liquid formulations and cured instantly using electron beam equipment, eliminating the need for solvent evaporation or heat curing processes. EB curable coatings are valued for their ability to improve productivity, reduce waste, and meet stringent environmental regulations. With advancements in formulation chemistry and EB curing technology, these coatings to expand their applications in new markets and offer sustainable solutions for coating and finishing needs.

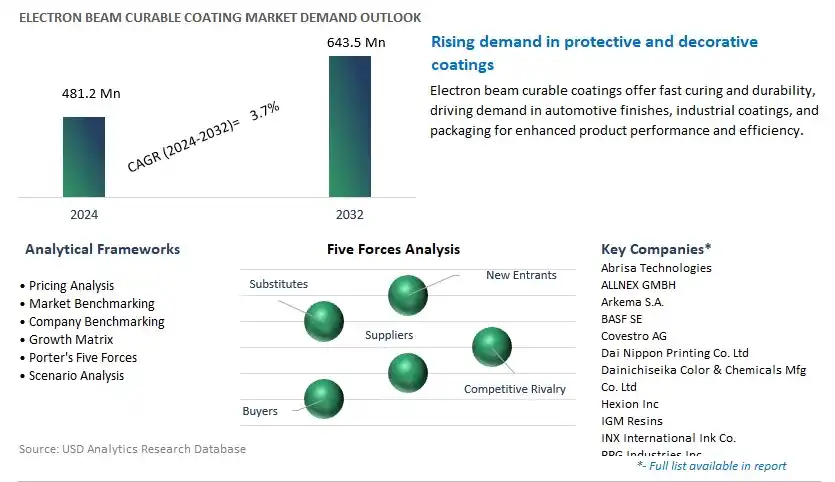

The market report analyses the leading companies in the industry including Abrisa Technologies, ALLNEX GMBH, Arkema S.A., BASF SE, Covestro AG, Dai Nippon Printing Co. Ltd, Dainichiseika Color & Chemicals Mfg Co. Ltd, Hexion Inc, IGM Resins, INX International Ink Co., PPG Industries Inc, R&D Coatings LLC, and others.

A significant trend in the electron beam curable coating market is the industry's shift towards sustainable coating solutions. With increasing environmental awareness and regulations aimed at reducing volatile organic compound (VOC) emissions, there is a growing demand for coatings that offer low environmental impact and comply with stringent eco-friendly standards. Electron beam curable coatings, which are solvent-free and produce minimal emissions during curing, are gaining popularity as sustainable alternatives to traditional solvent-based coatings. This trend is driven by the adoption of green chemistry principles and the desire among manufacturers to reduce their carbon footprint while maintaining high-performance coating properties. As sustainability becomes a key focus for industries such as packaging, automotive, and furniture, the demand for electron beam curable coatings is expected to continue growing, driving market expansion and innovation in environmentally friendly coating technologies.

A primary driver propelling the growth of the electron beam curable coating market is the numerous advantages offered by electron beam curing technology. Compared to traditional curing methods such as thermal or UV curing, electron beam curing offers several key benefits, including rapid curing speeds, superior adhesion, excellent chemical resistance, and enhanced durability. These advantages make electron beam curable coatings well-suited for demanding applications in industries such as aerospace, electronics, and medical devices, where performance, reliability, and fast production cycles are essential. Additionally, the ability of electron beam curable coatings to cure without the need for heat or photoinitiators reduces energy consumption and processing time, leading to cost savings and improved operational efficiency for manufacturers. As industries seek to optimize their coating processes and enhance product performance, the unique advantages of electron beam curing technology drive market adoption and growth.

An opportunity for growth within the electron beam curable coating market lies in the expansion into high-value niche markets and applications. While electron beam curable coatings are already widely used in industries such as printing, packaging, and automotive coatings, there are untapped opportunities in specialized sectors that require unique coating properties and performance characteristics. For example, the healthcare and pharmaceutical industries demand coatings with exceptional sterilization resistance and biocompatibility for medical devices and equipment. Similarly, the aerospace industry requires coatings that can withstand extreme environmental conditions, including high temperatures, UV radiation, and chemical exposure. By developing tailored electron beam curable coatings to address the specific needs of these niche markets, manufacturers can differentiate themselves, capture new revenue streams, and establish a strong foothold in high-value segments. Additionally, as advancements in formulation technology enable the customization of coating properties, there is potential for innovation and collaboration to unlock novel applications and address emerging market demands effectively.

Within the electron beam curable coating market segmented by end-user, the Packaging sector is the largest, driven by its extensive use in various packaging applications across industries. Electron beam curable coatings offer numerous advantages for packaging materials, including enhanced durability, chemical resistance, and rapid curing times. These coatings are widely utilized for food packaging, beverage containers, pharmaceutical packaging, and flexible packaging materials to provide protection against moisture, UV radiation, and mechanical damage while extending product shelf life. The Packaging segment benefits from the increasing demand for sustainable and high-performance packaging solutions driven by consumer preferences for convenience, safety, and environmental sustainability. Additionally, as regulations become more stringent regarding food safety and product quality, the adoption of electron beam curable coatings in packaging continues to grow. As a result, the Packaging segment maintains its dominance as the largest in the electron beam curable coating market, supported by its indispensable role in ensuring product integrity and safety throughout the supply chain.

Among the segments categorized by type in the electron beam curable coating market, the Transparent Electrodes segment is the fastest-growing, propelled by advancements in electronics and optoelectronics industries. Transparent electrodes are essential components in various electronic devices, including touch screens, displays, solar cells, and light-emitting diodes (LEDs). Electron beam curable coatings offer a unique combination of transparency, conductivity, and flexibility, making them ideal for creating high-performance transparent electrodes. The Transparent Electrodes segment benefits from the increasing demand for electronic devices with touch functionality, high-resolution displays, and energy-efficient lighting solutions. Additionally, as industries such as consumer electronics, automotive, and renewable energy continue to innovate and develop next-generation electronic devices and renewable energy technologies, the demand for transparent electrodes coated with electron beam curable coatings is experiencing rapid growth. As a result, the Transparent Electrodes segment is the fastest-growing in the electron beam curable coating market, driven by its crucial role in enabling advanced electronic and optoelectronic applications.

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Abrisa Technologies

ALLNEX GMBH

Arkema S.A.

BASF SE

Covestro AG

Dai Nippon Printing Co. Ltd

Dainichiseika Color & Chemicals Mfg Co. Ltd

Hexion Inc

IGM Resins

INX International Ink Co.

PPG Industries Inc

R&D Coatings LLC

*- List Not Exhaustive

TABLE OF CONTENTS

1 Introduction to 2024 Electron Beam Curable Coating Market

1.1 Market Overview

1.2 Quick Facts

1.3 Scope/Objective of the Study

1.4 Market Definition

1.5 Countries and Regions Covered

1.6 Units, Currency, and Conversions

1.7 Industry Value Chain

2 Research Methodology

2.1 Market Size Estimation

2.2 Sources and Research Methodology

2.3 Data Triangulation

2.4 Assumptions and Limitations

3 Executive Summary

3.1 Global Electron Beam Curable Coating Market Size Outlook, $ Million, 2021 to 2032

3.2 Electron Beam Curable Coating Market Outlook by Type, $ Million, 2021 to 2032

3.3 Electron Beam Curable Coating Market Outlook by Product, $ Million, 2021 to 2032

3.4 Electron Beam Curable Coating Market Outlook by Application, $ Million, 2021 to 2032

3.5 Electron Beam Curable Coating Market Outlook by Key Countries, $ Million, 2021 to 2032

4 Market Dynamics

4.1 Key Driving Forces of Electron Beam Curable Coating Industry

4.2 Key Market Trends in Electron Beam Curable Coating Industry

4.3 Potential Opportunities in Electron Beam Curable Coating Industry

4.4 Key Challenges in Electron Beam Curable Coating Industry

5 Market Factor Analysis

5.1 Value Chain Analysis

5.2 Competitive Landscape

5.2.1 Global Electron Beam Curable Coating Market Share by Company (%), 2023

5.2.2 Product Offerings by Company

5.3 Porter’s Five Forces Analysis

5.4 Pricing Analysis and Outlook

6 Growth Outlook Across Scenarios

6.1 Growth Analysis-Case Scenario Definitions

6.2 Low Growth Scenario Forecasts

6.3 Reference Growth Scenario Forecasts

6.4 High Growth Scenario Forecasts

7 Global Electron Beam Curable Coating Market Outlook by Segments

7.1 Electron Beam Curable Coating Market Outlook by Segments, $ Million, 2021- 2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

8 North America Electron Beam Curable Coating Market Analysis and Outlook To 2032

8.1 Introduction to North America Electron Beam Curable Coating Markets in 2024

8.2 North America Electron Beam Curable Coating Market Size Outlook by Country, 2021-2032

8.2.1 United States

8.2.2 Canada

8.2.3 Mexico

8.3 North America Electron Beam Curable Coating Market size Outlook by Segments, 2021-2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

9 Europe Electron Beam Curable Coating Market Analysis and Outlook To 2032

9.1 Introduction to Europe Electron Beam Curable Coating Markets in 2024

9.2 Europe Electron Beam Curable Coating Market Size Outlook by Country, 2021-2032

9.2.1 Germany

9.2.2 France

9.2.3 Spain

9.2.4 United Kingdom

9.2.4 Italy

9.2.5 Russia

9.2.6 Norway

9.2.7 Rest of Europe

9.3 Europe Electron Beam Curable Coating Market Size Outlook by Segments, 2021-2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

10 Asia Pacific Electron Beam Curable Coating Market Analysis and Outlook To 2032

10.1 Introduction to Asia Pacific Electron Beam Curable Coating Markets in 2024

10.2 Asia Pacific Electron Beam Curable Coating Market Size Outlook by Country, 2021-2032

10.2.1 China

10.2.2 India

10.2.3 Japan

10.2.4 South Korea

10.2.5 Indonesia

10.2.6 Malaysia

10.2.7 Australia

10.2.8 Rest of Asia Pacific

10.3 Asia Pacific Electron Beam Curable Coating Market size Outlook by Segments, 2021-2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

11 South America Electron Beam Curable Coating Market Analysis and Outlook To 2032

11.1 Introduction to South America Electron Beam Curable Coating Markets in 2024

11.2 South America Electron Beam Curable Coating Market Size Outlook by Country, 2021-2032

11.2.1 Brazil

11.2.2 Argentina

11.2.3 Rest of South America

11.3 South America Electron Beam Curable Coating Market size Outlook by Segments, 2021-2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

12 Middle East and Africa Electron Beam Curable Coating Market Analysis and Outlook To 2032

12.1 Introduction to Middle East and Africa Electron Beam Curable Coating Markets in 2024

12.2 Middle East and Africa Electron Beam Curable Coating Market Size Outlook by Country, 2021-2032

12.2.1 Saudi Arabia

12.2.2 UAE

12.2.3 Oman

12.2.4 Rest of Middle East

12.2.5 Egypt

12.2.6 Nigeria

12.2.7 South Africa

12.2.8 Rest of Africa

12.3 Middle East and Africa Electron Beam Curable Coating Market size Outlook by Segments, 2021-2032

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

13 Company Profiles

13.1 Company Snapshot

13.2 SWOT Profiles

13.3 Products and Services

13.4 Recent Developments

13.5 Financial Profile

Abrisa Technologies

ALLNEX GMBH

Arkema S.A.

BASF SE

Covestro AG

Dai Nippon Printing Co. Ltd

Dainichiseika Color & Chemicals Mfg Co. Ltd

Hexion Inc

IGM Resins

INX International Ink Co.

PPG Industries Inc

R&D Coatings LLC

14 Appendix

14.1 Customization Offerings

14.2 Subscription Services

14.3 Related Reports

14.4 Publisher Expertise

By End-User

Aerospace

Electrical and Electronics

Automotive

Packaging

Others

By Type

Anti-reflection

Transparent Electrodes

Filter Coating

Others

Countries Analyzed

North America (US, Canada, Mexico)

Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South East Asia, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Rest of Middle East, South Africa, Egypt, Rest of Africa)

Global Electron Beam Curable Coating Market Size is valued at $481.2 Million in 2024 and is forecast to register a growth rate (CAGR) of 3.7% to reach $643.5 Million by 2032.

Emerging Markets across Asia Pacific, Europe, and Americas present robust growth prospects.

Abrisa Technologies, ALLNEX GMBH, Arkema S.A., BASF SE, Covestro AG, Dai Nippon Printing Co. Ltd, Dainichiseika Color & Chemicals Mfg Co. Ltd, Hexion Inc, IGM Resins, INX International Ink Co., PPG Industries Inc, R&D Coatings LLC

Base Year- 2023; Estimated Year- 2024; Historic Period- 2018-2023; Forecast period- 2024 to 2032; Currency: Revenue (USD); Volume